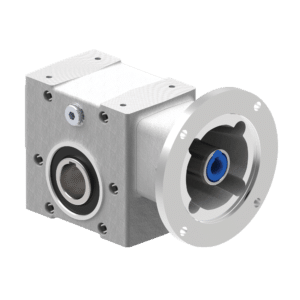

Series B Gearbox

Adaptable Power

The Series B gearbox is a highly flexible and economical right angle gearing solution. Directly interchangeable with competitor reducers, the Series B features a lightweight aluminum housing which provides improved thermal performance. No other reducers offer the flexibility, performance, and reliability that you expect from Cone Drive.

Key Features

- Conex Proprietary Worm Gearing

- Two Input Bearings

- Lightweight, Aluminum Construction

- Non-Fretting Motor Connection

- Optional Washdown Design

- USDA Approved White Epoxy Paint Available

- Best in Class Lead Times

- 2 Year Warranty

SERIES B GEARBOX SPECIFICATIONS

- Center Distance: 1.33 thru 3.54 in

- Ratio: 5:1 thru 3,600:1

- Reductions: Single or double

- Output Torque (Constant Speed): < 6,370 lb-in

- Available Versions: Horizontal or vertical base, output bracket, torque arm

- Input Shaft: Solid, single extended

- Output Shaft: Solid (single or double extended), hollow

- Lubricant: Factory filled with synthetic lubricant

- I.P. Rating: IP 55

FAQ's

Cone Drive’s double enveloping worm gear has an hourglass shape and the gear is machined with unique contours to ensure maximum contact between the components. This added contact creates a high torque capacity, high durability worm gear. Cone Drive’s worm gear design provides you a higher load capacity, lower contact stress, and greater shock capacity. These improved ratings offer you the flexibility to downsize the gearbox to save space or increase the motor to get more power

Please refer to the Approved Lubrication List.

Please review the Installation and Maintenance manual for proper oil amounts.

User will assume risk of non-approved lubricants which may affect performance of the gearbox and void warranty.

Normal gearbox operating temperature measured at the oil sump area of the housing should not exceed 100°F (38°C) above ambient temperature or 200°F (93°C) maximum. If the gearbox operating temperature exceeds these limits, shut down the unit and contact Cone Drive. Excessive oil sump temperature is indicative of overloading, misalignment, or improper or marginal lubrication. Continuous operation of the gearbox with the oil sump temperature above 200°F (93°C) will result in failure of the gearbox

Backdriving or self-locking cannot be guaranteed by Cone Drive, therefore a brake mechanism is always recommended

A fan should be used whenever the absorbed power in a continuous application exceeds the thermal horsepower rating of the unit

Yes – Please contact our Repair & Rebuild center.

Zero backlash units are designed for cyclic (non-continuous) positioning applications. Ratios below 20:1 are not suggested. Long duty cycle applications can cause excessive gearbox heat and wear. The motor horsepower required for a zero backlash design is higher than that of a standard design gearset

Yes. Our engineering team at Cone Drive has years of experience creating customized solutions for our customers. Please reach out to our Application Engineering team to get started.

Cone Drive has developed a specialized sectioned worm design to achieve zero backlash. As the gear wears, the worm self-adjusts to compensate and maintain zero backlash.

PRODUCT DEVELOPMENT

The Cone Drive Product Development Laboratory is a state-of-the-art facility directly adjacent to our Traverse City, Michigan manufacturing location. The lab has the capacity to test a wide range of gear reducer products, for both Cone Drive products as well as those manufactured by other companies. The lab includes capability to run a wide variety of tests including load testing for evaluating reducer performance and operating efficiency.

TEST + CONTROL

PRODUCT MEASUREMENT

- Six product testing stands

- Servo cyclic control

- Simulated inertial loading

- Constant torque/load

- Durability/validation

- Accelerated life test

- Lubricant evaluation

- Static loading & stiffness

- Displacement & motion

- Torque

- Thermal

- Efficiency

- Vibration

- Basic noise

- Transmission accuracy