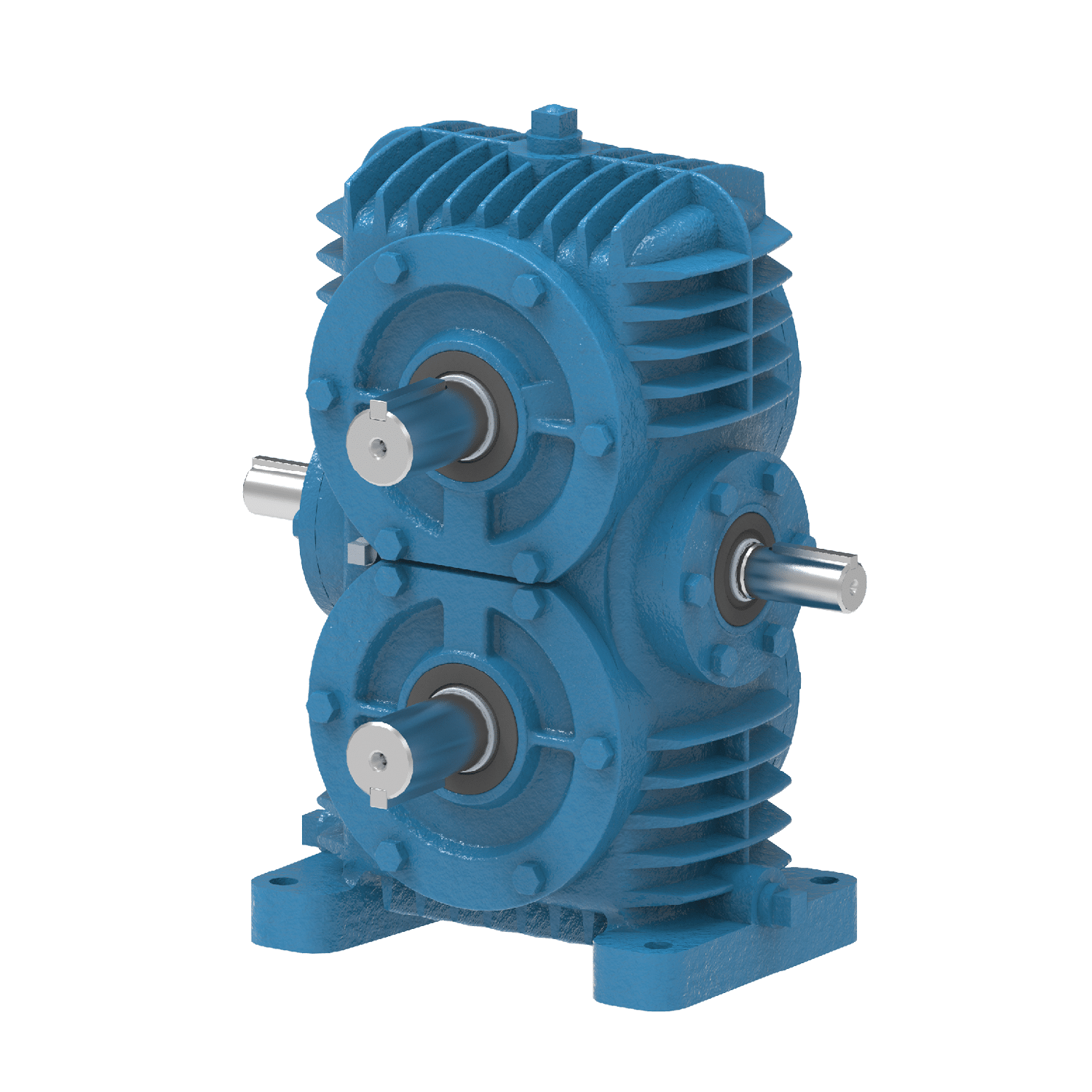

A WIDE VARIETY OF INDUSTRIAL AND PRECISION GEARING SOLUTIONS

Whether your application requires triple reduction torque or zero backlash precision, Cone Drive has you covered. We offer a wide product range including industrial gearboxes, precision zero backlash worm gears, inline precision gearing, slewing drives and bearings, and fully customizable products tailored to your needs. For almost 100 years, Cone Drive has been supplying gearing solutions to provide torque to a variety of applications and markets world wide.

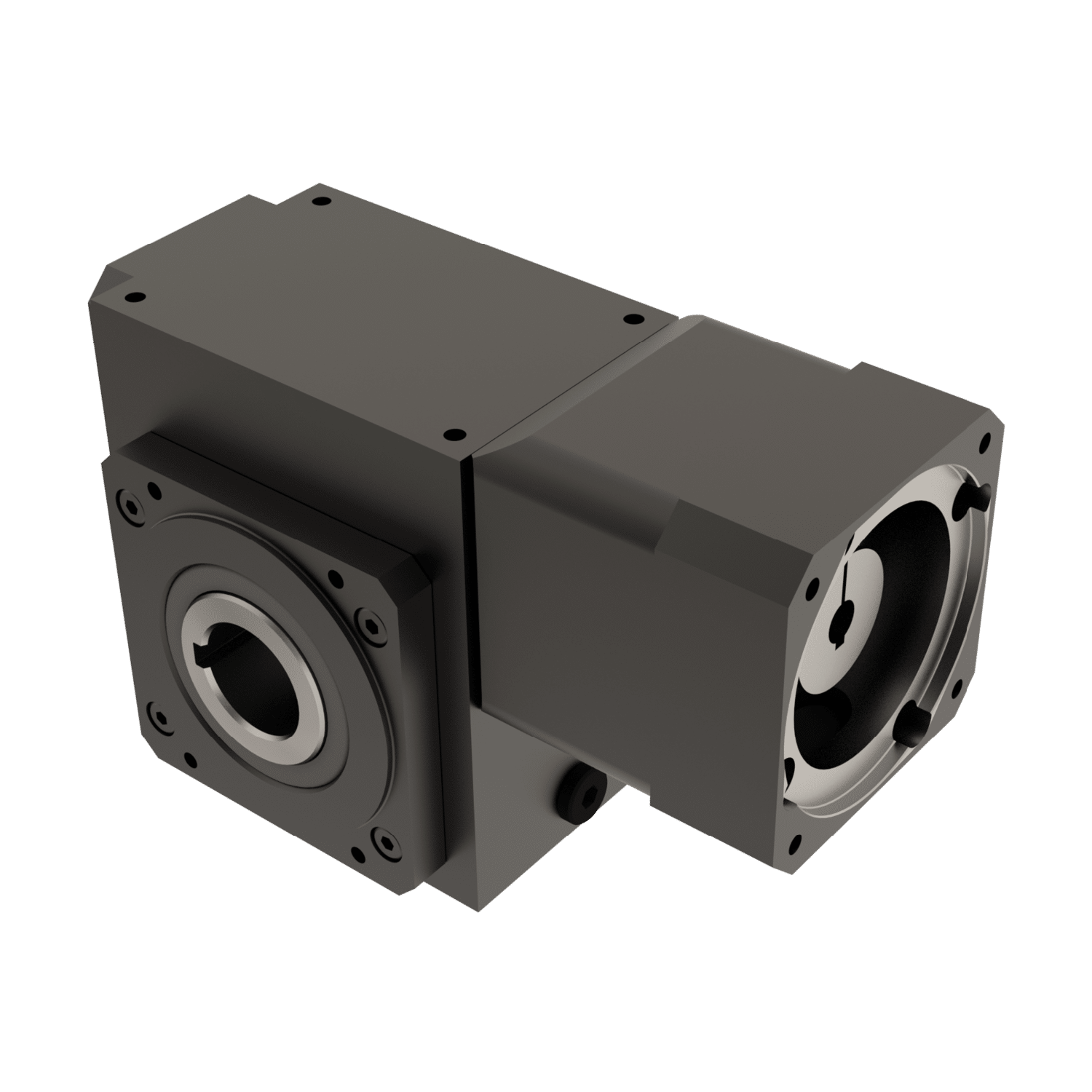

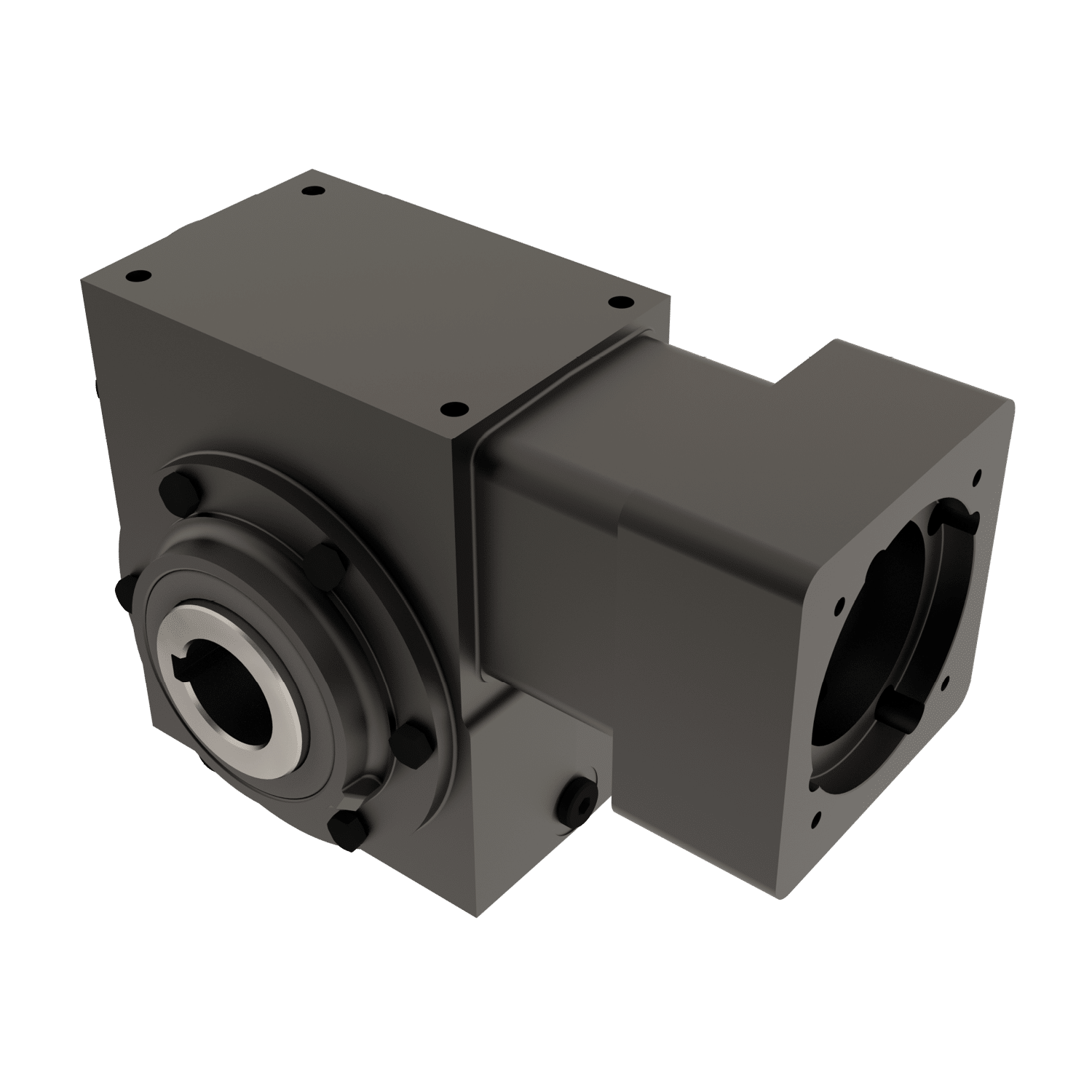

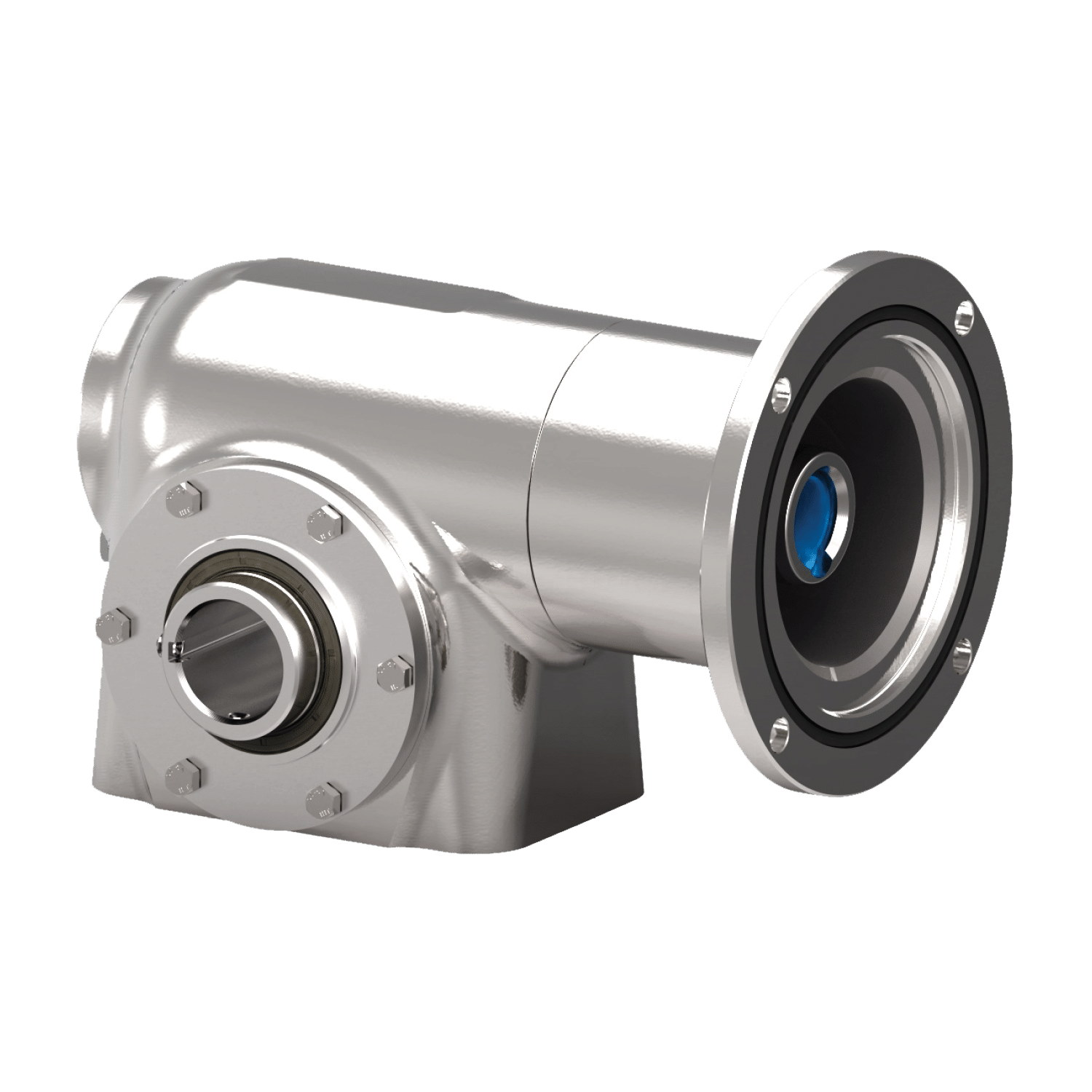

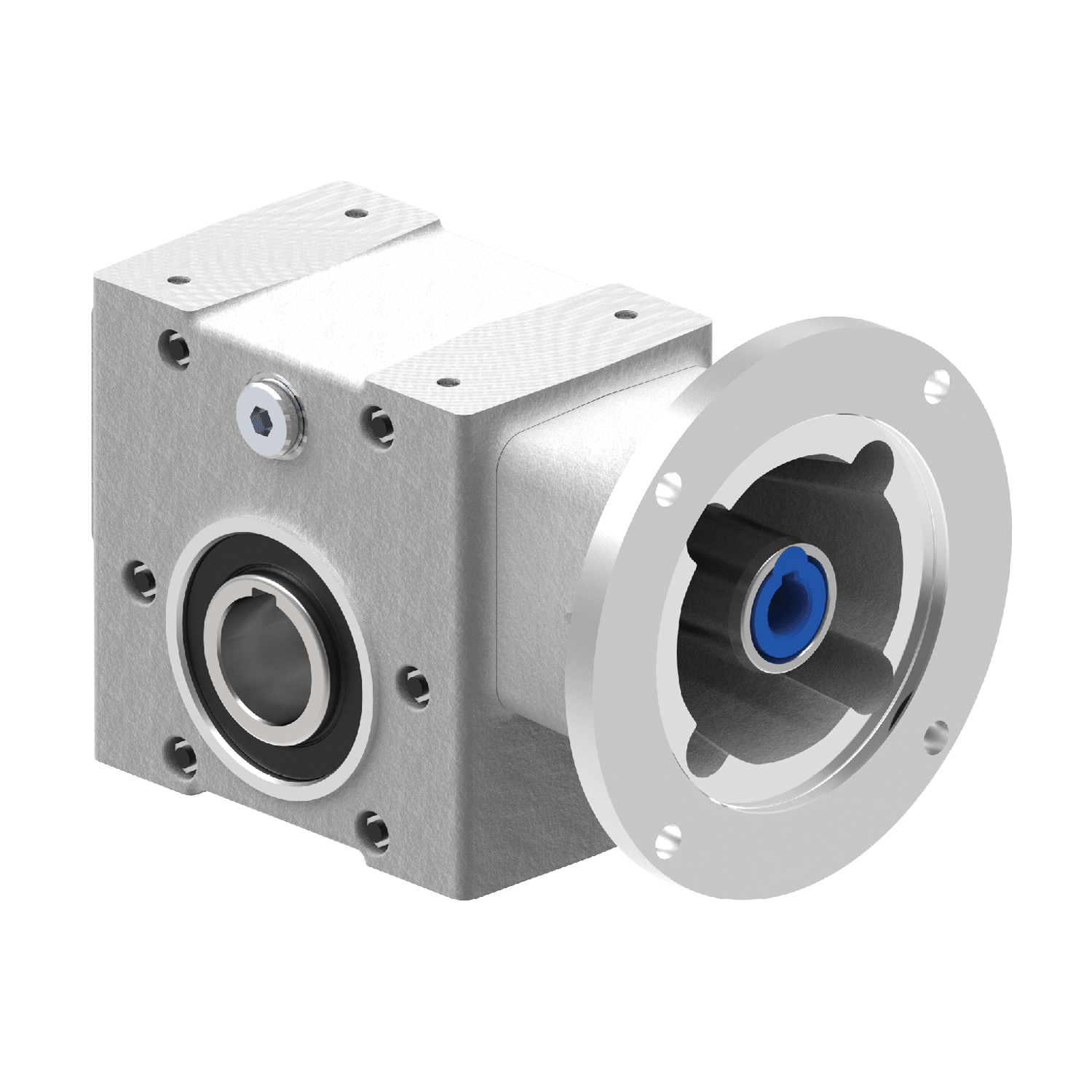

SERVO DRIVEN PRODUCTS

Cone Drive’s servo driven gearing products are adaptable to a wide variety of servo motor sizes.

Standard, low, and zero backlash options are available to meet the requirements of your most demanding precision applications.

If you require a motor adaptation that we currently do not have listed as standard, Cone Drive’s robust team of engineers can quickly crank out a design to mate up with most any servo motor on the market.

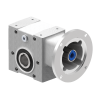

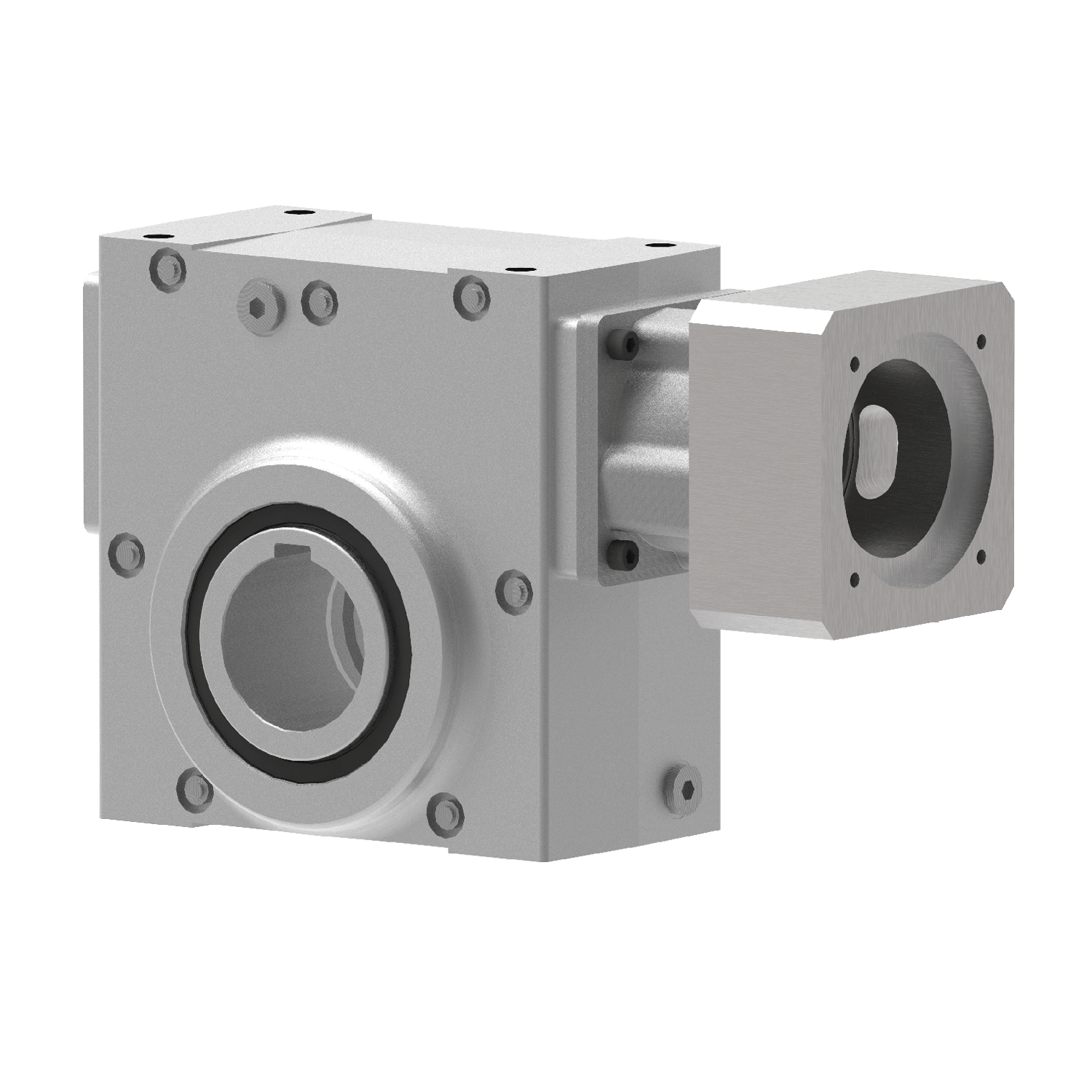

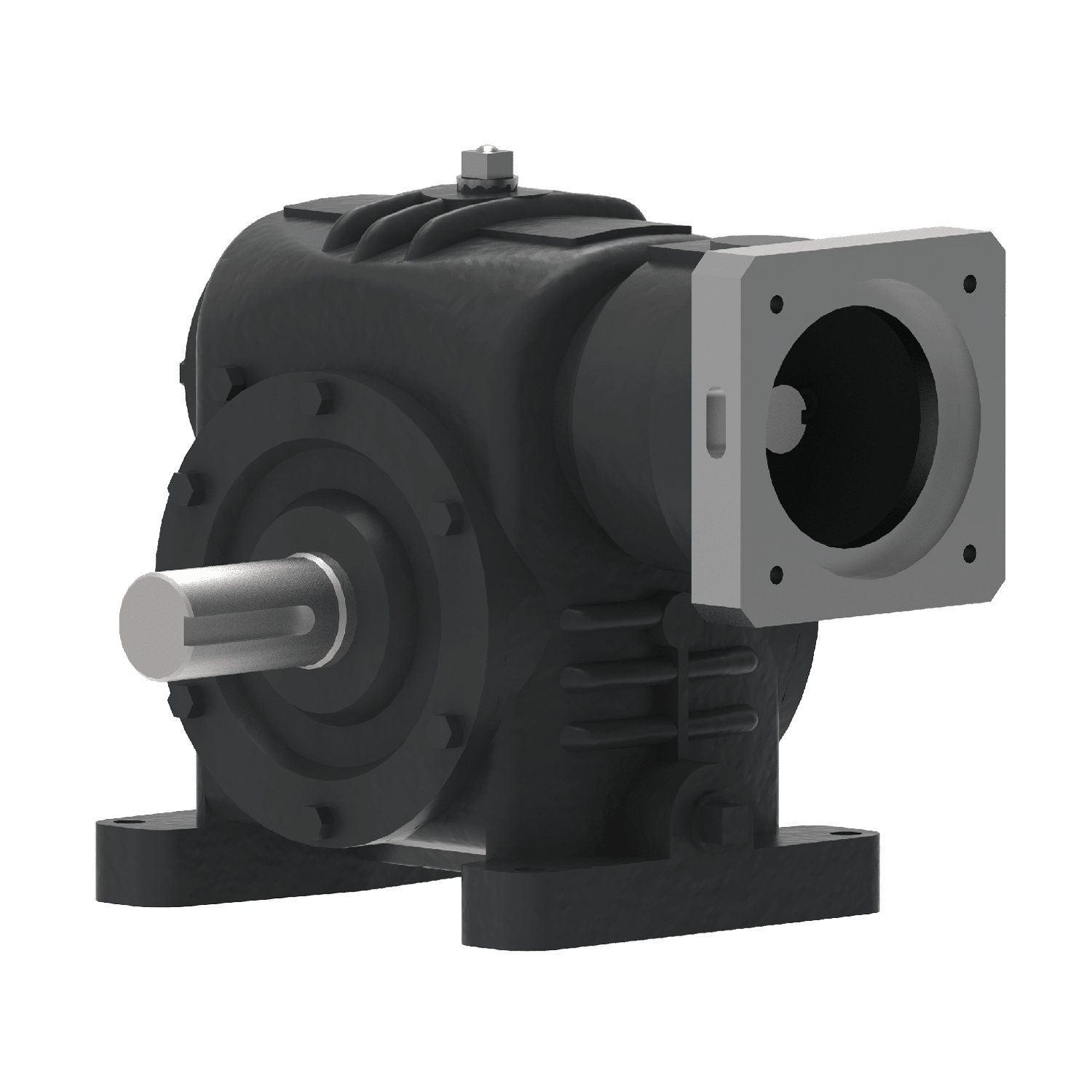

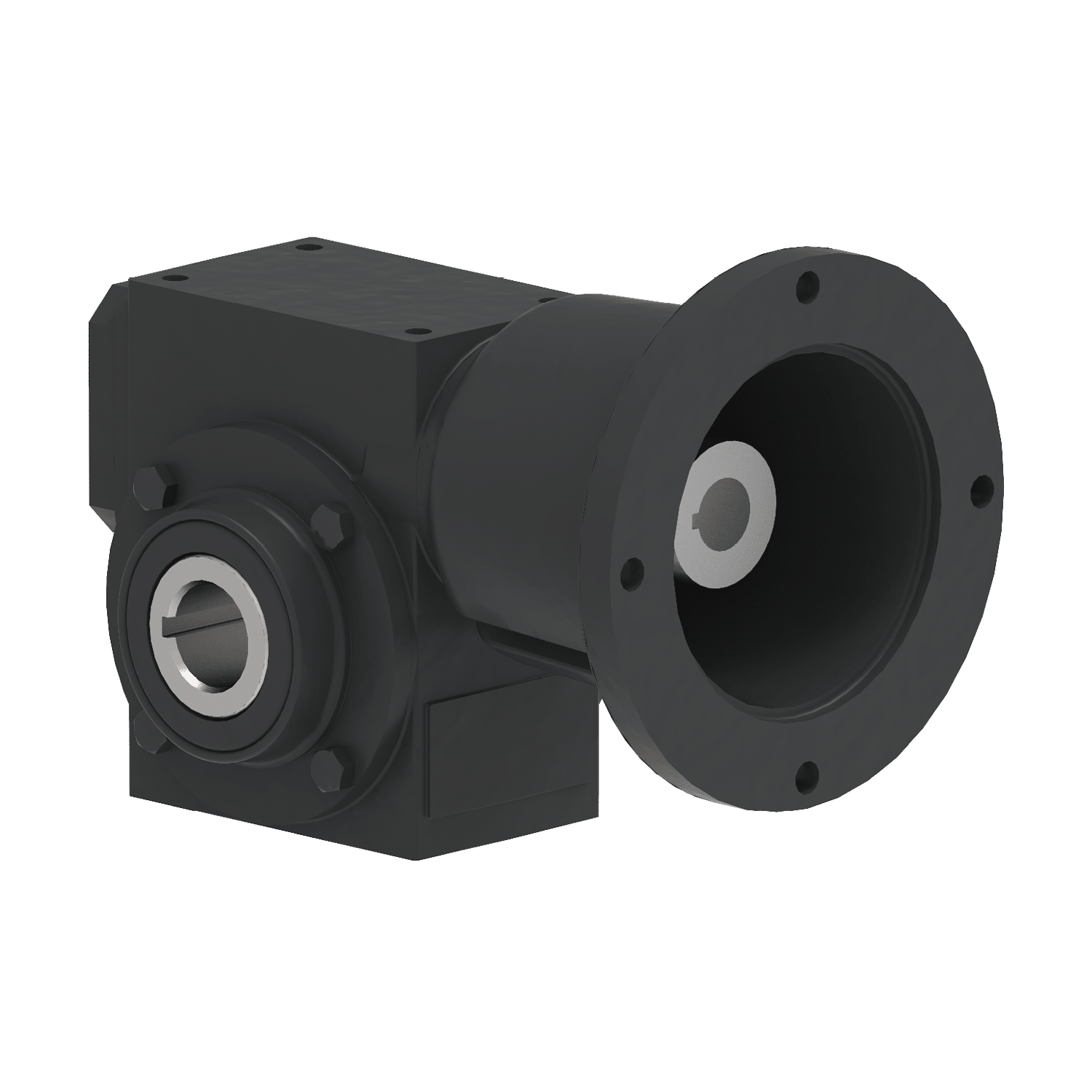

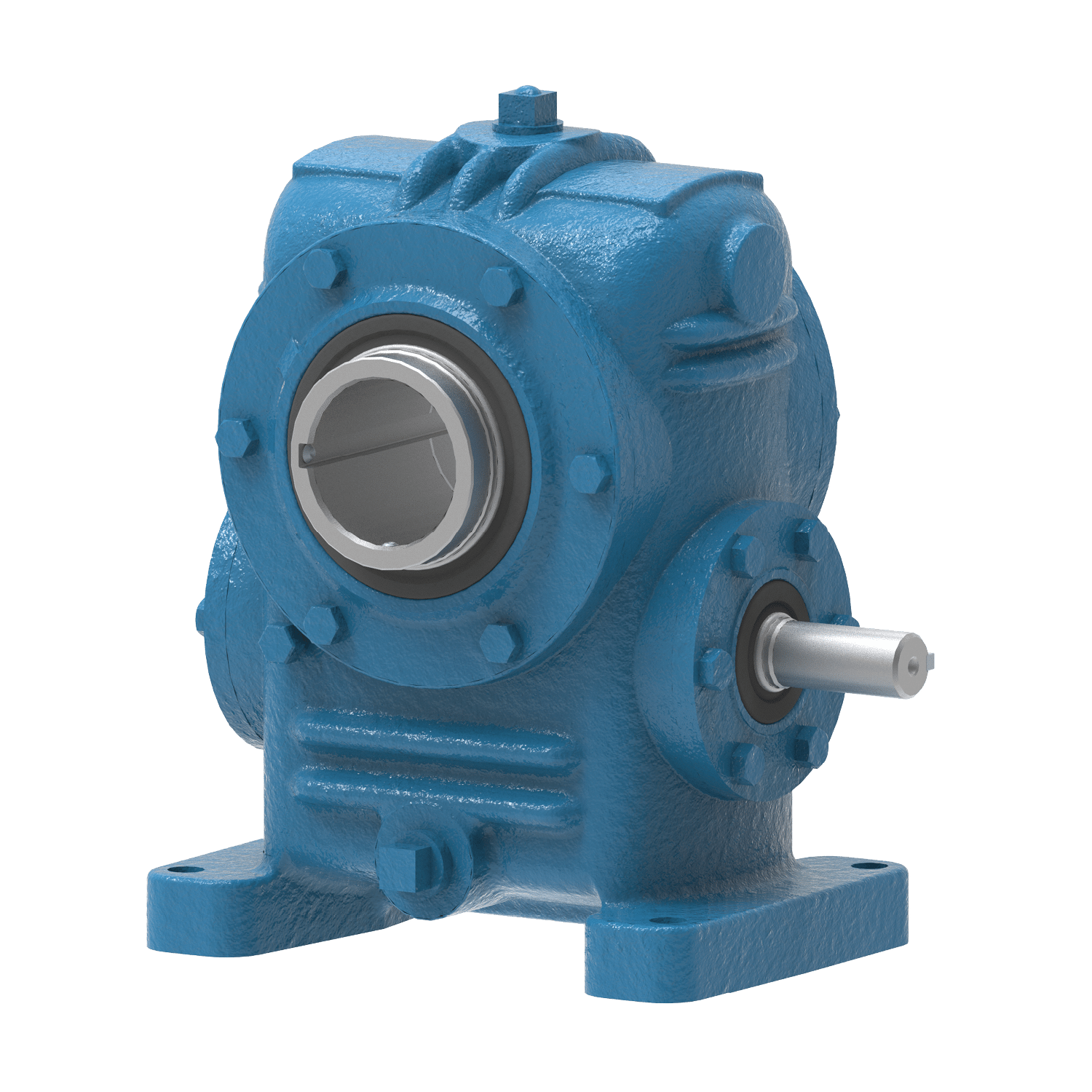

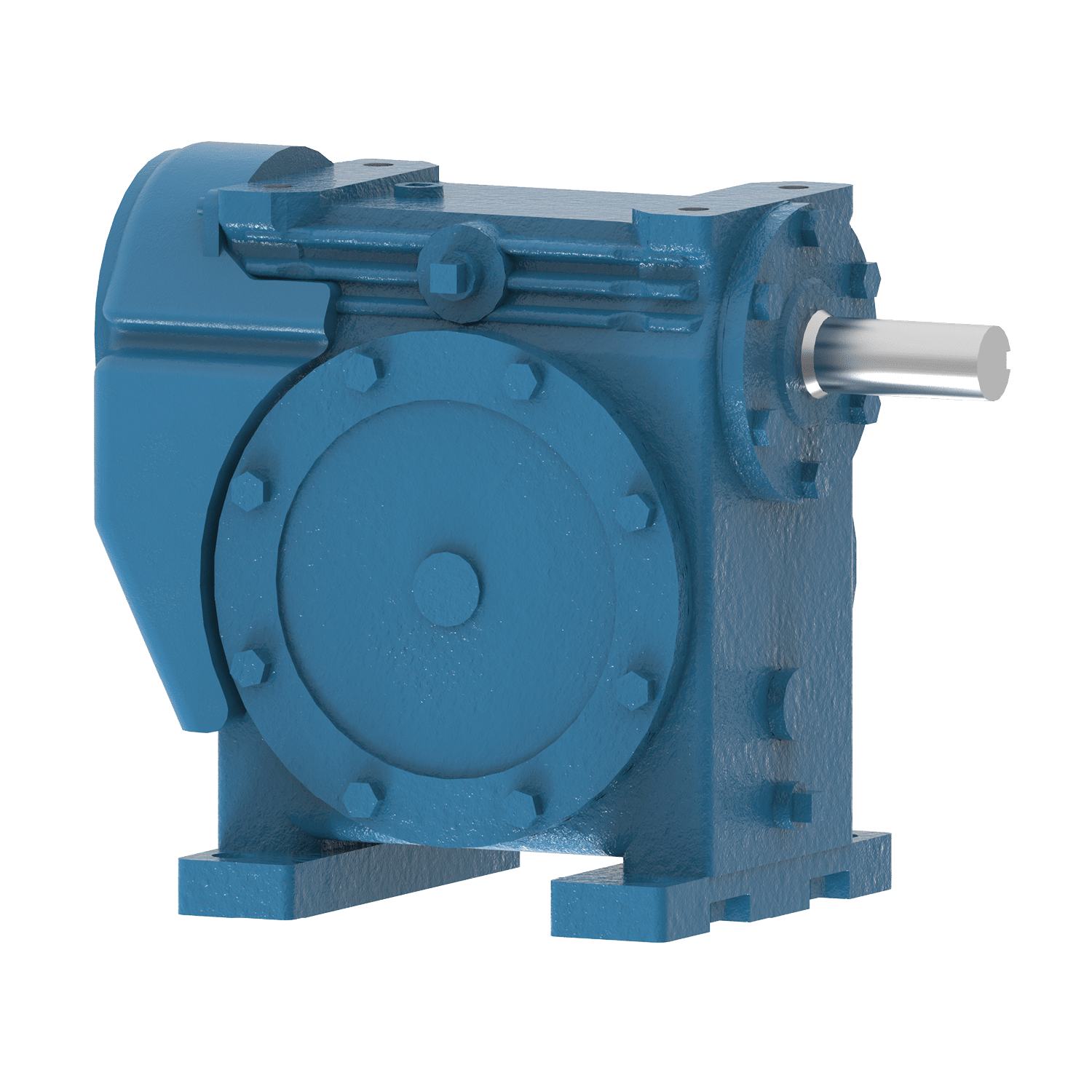

NEMA DRIVEN PRODUCTS

Cone Drive’s NEMA driven gearing products are adaptable to a wide variety of motor sizes.

In addition to gearboxes with an integrated motor adapter flange, Cone Drive also offers a reducer style that can be driven by a belt, chain, etc.

Cone Drive’s NEMA motor mount gearboxes are equipped with a non fretting quill design that makes motor removal a simple and quick task.

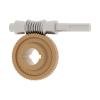

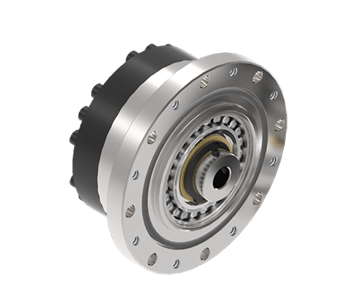

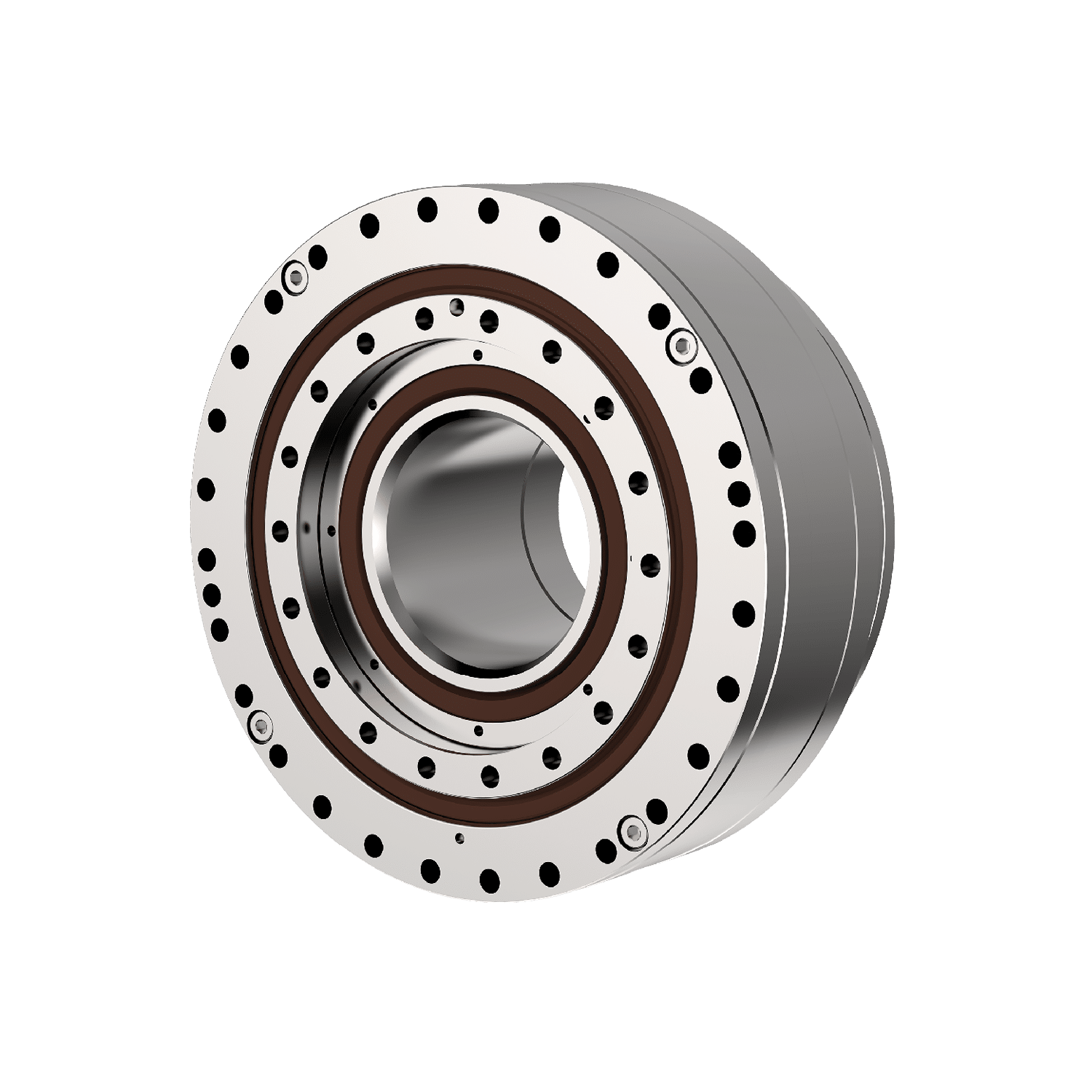

INLINE SOLUTIONS

Cone Drive’s inline solutions are the ultimate in precision motion control technology. Our harmonic product range includes gearheads and component sets and our cycloidal gearing can be supplied with an integrated drive. Our planetary drives are compact and offer an affordable high efficiency and low backlash design.

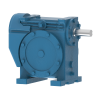

SLEWING SOLUTIONS

Cone Drive’s slewing technology provides a large ratio in a single stage of gearing. The slew bearing and gears are assembled into a low profile, self-retaining, and ready-to-install housing optimized for weight and performance. Our highly adaptable slew gearing feature strong shock resistance, long life performance, and smooth rotation.

SOLAR TRACKING

Cone Drive has a long history of developing custom solutions for both single-axis and dual-axis solar tracker drives. As a global solar drive manufacturer we have the experience and the reach to deliver highly effective solar solutions.

SATELLITE COMMUNICATION POSITIONING

PRECISION • MOTION CONTROL • TECHNOLOGY

We design and manufacture worm gears, worm gearboxes, slew bearings, slew drives, harmonic, and cycloidal gearing. With a history of gearbox manufacturing that spans nearly 100 years, we are a world leader in precision motion control technology. With Cone Drive you can always find the right solution for your application with the highest quality products and the lead times you require.

PRODUCT DEVELOPMENT

The Cone Drive Product Development Laboratory is a state-of-the-art facility directly adjacent to our Traverse City, Michigan manufacturing location. The lab has the capacity to test a wide range of gear reducer products, for both Cone Drive products as well as those manufactured by other companies. The lab includes capability to run a wide variety of tests including load testing for evaluating reducer performance and operating efficiency.

TEST + CONTROL

PRODUCT MEASUREMENT

- Six product testing stands

- Servo cyclic control

- Simulated inertial loading

- Constant torque/load

- Durability/validation

- Accelerated life test

- Lubricant evaluation

- Static loading & stiffness

- Displacement & motion

- Torque

- Thermal

- Efficiency

- Vibration

- Basic noise

- Transmission accuracy