CONE DRIVE HARMONIC SOLUTIONS® STRAIN WAVE GEARING

Cone Drive Harmonic Solutions® are designed with a style of gearing known as strain wave gearing.

Cone Drive harmonic strain wave gearing is compact and torque dense providing a perfect solution for the automation market.

In addition to our standard product offerings, we are able to quickly develop custom solutions to meet your specific application requirements.

Wave Generator

The wave generator is comprised of a specially designed thin raced ball bearing that is fitted onto an elliptical hub. A drive shaft connects to the hub of the wave generator, and the ball bearing transmits torque to the gear mesh.

Flex Spline

(OD Spline)

The wave generator is pressed into the flex spline. This deforms the flex spline to the shape of the wave generator ellipse and allows tooth engagement with the circular spline.

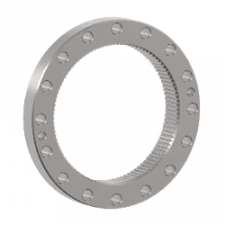

Circular Spline (ID Spline)

When the gearing is assembled, the teeth of the flex spline engage across the major axis of the wave generator ellipse. With the assembly complete, the rotation of the wave generator hub creates gear reduction between the flex spline and circular spline.

Our harmonic gearing has high positional accuracy, high torsional stiffness, and zero backlash. The circular spline, flex spline, and wave generator work together to create the strain wave gearing reduction. The flex spline is a thin walled, flexible design that flexes with the profile of the wave generator. The flex spline contains two fewer teeth relative to the circular spline. For every rotation of the wave generator, the flex spline rotates at a slower rate in the reverse direction relative to the circular spline.

Custom is Our Specialty

Our experienced team of customer service representatives, application engineers, design engineers and manufacturing engineers are ready and willing to take on a challenge. Let us put our expertise to work and develop a solution customized to fit your needs. We can design and manufacture any type of worm drive gearbox application that you require.

Cone Drive Quality

- Quality Engineering: We will design the right gearbox for your application and build it with the finest materials and components.

- Quality Manufacturing: We operate with a strict attention to detail and manufacture to exact tolerances and dimensions. Your gearbox will be built with precision and accuracy.

- Quality Service: When you need assistance with installation, Cone Drive will be there to support you. We are fully committed to offering you service before and after the sale.

We Have Stood the Test of Time

For nearly 100 years, we have been making quality, durable worm gears. Our double-enveloping worm gearboxes drive equipment in mining, steel, aerospace, automotive, printing, packaging, and solar power world-wide. When you choose Cone Drive, you have the confidence of knowing that our many years of experience are behind every unit that we build.

Our Team

Cone Drive has a team of highly qualified, high character individuals to help if you have questions at any time throughout the purchasing process. Give us a call and we will offer dedicated, personal support to help get you started and identify what product will best fit your application.

FAQ's

Traverse City, MI, USA

Please contact our Customer Service team with your selected style, size, ratio, and quantity.

1-888-994-2663 (toll free)

1-231-946-8410 (International)

2 – 4 weeks

The expected life for a standard unit varies by style, size, and ratio.

Please contact our Customer Service team for additional information.

1-888-994-2663 (toll free)

1-231-946-8410 (International)

Standard parts could be as low as a 2-4 weeks. Custom features may change lead time.

Yes, please reach out to our Application Engineers for your specific needs.