A WIDE VARIETY OF INDUSTRIAL AND PRECISION GEARING SOLUTIONS

Whether your application requires triple reduction torque or zero backlash precision, Cone Drive has you covered. We offer a wide product range including industrial gearboxes, precision zero backlash worm gears, inline precision gearing, slewing drives and bearings, and fully customizable products tailored to your needs. For almost 100 years, Cone Drive has been supplying gearing solutions to provide torque to a variety of applications and markets world wide.

Cone Drive’s servo driven gearing products are adaptable to a wide variety of servo motor sizes.

Standard, low, and zero backlash options are available to meet the requirements of your most demanding precision applications. As a global servo gearbox manufacturer we have the experience and the reach to deliver highly effective gearing solutions.

If you require a motor adaptation that we currently do not have listed as standard, Cone Drive’s robust team of engineers can quickly crank out a design to mate up with most any servo motor on the market.

Cone Drive’s NEMA driven gearing products are adaptable to a wide variety of motor sizes.

In addition to gearboxes with an integrated motor adapter flange, Cone Drive also offers a reducer style that can be driven by a belt, chain, etc.

Cone Drive’s NEMA motor mount gearboxes are equipped with a non fretting quill design that makes motor removal a simple and quick task.

Cone Drive’s cup-style harmonic gearing solutions are designed for compact, high-torque applications requiring precise, zero-backlash motion control. In this configuration, the torque is transmitted through the closed (bottom) surface of the cup, providing a lightweight, space-efficient solution ideal for tight integration.

The CBC, CBCF-, CBC-L, CBG, and CBGF- series offer features such as integrated cross-roller bearings and industry-standard mounting interfaces—and are fully customizable to meet specific application and performance requirements.

Cone Drive’s hat-style harmonic gearing solutions are built for high-precision, high-torque applications where smooth motion and robust load handling are essential. In this configuration, the torque is transmitted through the flanged brim of the hat, providing a stable and accessible interface for integration.

The HBC, HBCF-, HBG, HBGT-, and HBGHL series include options such as housed outputs, large hollow shafts, sealed designs, and integrated cross-roller bearings—making them ideal for robotics, automation, and demanding industrial environments. These solutions are fully customizable to meet unique space, torque, and performance requirements.

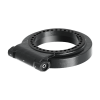

Cone Drive’s ring-style harmonic gearing solutions—RLC and RBC—are designed for applications requiring a compact, high-precision solution with flexible integration. In this configuration, the load is supported through the outer ring, with mounting typically done on the circular shaped ID Spline, allowing for seamless integration into rotating systems such as turntables or positioning platforms.

The RLC offers an ultra-compact design, while the RBC provides increased torque capacity in while maintaining a compact footprint. Both models are fully customizable to meet exact torque, ratio, and mounting interface requirements—making them ideal for robotics, automation, and space-constrained systems.

Cone Drive’s integrated harmonic actuator solutions—including the GMA-H, GMA-S, and Harmonic cup with NEMA stepper motor—combine high-efficiency motors with precision harmonic gearing in ultra-compact assemblies. These solutions offer excellent power density, zero backlash, and flexible mounting options, with the GMA-S optimized for lightweight applications and the GMA-H designed for higher torque needs. The Harmonic Stepper model integrates directly with NEMA stepper motors, providing a ready-to-use, space-saving solution for robotics, automation, and compact motion systems.

All models are fully customizable to meet specific performance and envelope requirements.

Spinea’s TwinSpin® cycloidal gears offer a versatile range of high-precision, high-torque reducers designed for demanding motion control applications. Across the T, E, H, M, G, GH and W Series, TwinSpin® cycloidal gears deliver zero backlash, high torsional stiffness, and exceptional load-handling capabilities in compact, integrated designs.

Whether you’re focused on compactness (E & M Series), heavy-duty performance (H, G, GH Series), or modularity (T & W Series), TwinSpin® gear units provide reliable and efficient solutions for robotics, machine tools, automation, and more. All models are fully customizable to meet exact application and integration requirements.

Spinea’s DriveSpin® series offers a comprehensive lineup of high-performance cycloidal servo actuators designed for dynamic motion control in robotics, automation, and precision equipment. Available in Standard (DS), Hollow Shaft (DSH), Modular (DSM), and Flat (DSF) versions, the DriveSpin® line delivers high torque density, zero backlash, and excellent positioning accuracy in compact, sealed designs.

Each series is engineered for specific integration needs—whether it’s the space-saving DSF, the cable-routing capability of the DSH, or the flexibility of the DSM’s modular build. All DriveSpin® actuators are fully customizable and built to handle high loads, fast cycles, and precise positioning with repeatable reliability.

Spinea’s MoveSpin® series is a complete family of cycloidal-based traction and steering units purpose-built for autonomous mobile robots (AMRs) and automated guided vehicles (AGVs). From the ultra-low-profile MS 140-500 and fully rotating MS 160-500, to heavy-duty differential units like the MS 200-500 and compact MS 200-060, the lineup supports a wide range of platform sizes and payload requirements. The MS 160-500 DD provides designers with added flexibility for customized steering architectures.

Designed for tight integration, high load capacity, and reliable mobility, all MoveSpin® models are fully customizable and optimized for safety, maneuverability, and efficiency in mobile automation.

SLEWING SOLUTIONS

Cone Drive’s slewing technology provides a large ratio in a single stage of gearing. The slew bearing and gears are assembled into a low profile, self-retaining, and ready-to-install housing optimized for weight and performance. Our highly adaptable slew gearing feature strong shock resistance, long life performance, and smooth rotation.

SOLAR TRACKING

Cone Drive has a long history of developing custom solutions for both single-axis and dual-axis solar tracker drives. As a global solar drive manufacturer we have the experience and the reach to deliver highly effective solar solutions.

SATELLITE COMMUNICATION POSITIONING

PRECISION • MOTION CONTROL • TECHNOLOGY

We design and manufacture worm gears, worm gearboxes, slew bearings, slew drives, harmonic, and cycloidal gearing. With a history of manufacturing that spans nearly 100 years, we are the only gearbox supplier you need. With Cone Drive you can always find the right solution for your application with the highest quality products and the lead times you require.

PRODUCT DEVELOPMENT

The Cone Drive Product Development Laboratory is a state-of-the-art facility directly adjacent to our Traverse City, Michigan manufacturing location. The lab has the capacity to test a wide range of gear reducer products, for both Cone Drive products as well as those manufactured by other companies. The lab includes capability to run a wide variety of tests including load testing for evaluating reducer performance and operating efficiency.

TEST + CONTROL

PRODUCT MEASUREMENT

- Six product testing stands

- Servo cyclic control

- Simulated inertial loading

- Constant torque/load

- Durability/validation

- Accelerated life test

- Lubricant evaluation

- Static loading & stiffness

- Displacement & motion

- Torque

- Thermal

- Efficiency

- Vibration

- Basic noise

- Transmission accuracy