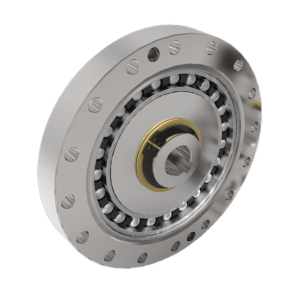

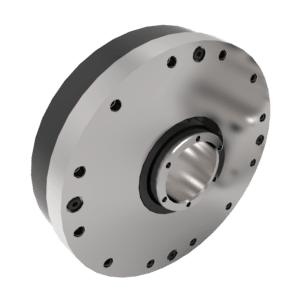

Cone Drive Harmonic Solutions®

Ultimate Precision

Cone Drive’s harmonic gearing is zero to low backlash by design. It provides high transmission accuracy and can support a high ratio reduction in a single stage with low inertia. The highly accurate, torque dense design makes harmonic gears the perfect solution for ultimate precision motion control applications.

We manufacture a wide range of strain wave gearing options in our line of Cone Drive Harmonic Solutions®.

Key Features

- Ring, Cup, and Hat Styles Available

- Component Sets and Gearheads

- Low to Zero Backlash

- High Transmission Accuracy

- Customizations Available Upon Request

- Manufactured and Assembled in Controlled Environment

- Competitive Lead Times

- 1 Year Warranty

HARMONIC GEARING SPECIFICATIONS

- Sizes: 11 thru 32

- Ratio: 50:1 thru 160:1

- Nominal Backlash: < 1 mRad

- Continuous Output Torque: < 172 Nm

- Peak Output Torque: < 824 Nm

- Standard Input Options: Keyed or set screws (including Oldman style coupling)

- Custom Input Options: Throughbore, solid input, dowel pins, tapped holes, piloted stepper/servo motor ready, special materials and coatings

- Configurations: Component gearset or gearhead, sealed, throughbore, lightweight, and other options available

FAQ's

Traverse City, MI, USA

Please contact our Customer Service team with your selected style, size, ratio, and quantity.

1-888-994-2663 (toll free)

1-231-946-8410 (International)

2 – 4 weeks

The expected life for a standard unit varies by style, size, and ratio.

Please contact our Customer Service team for additional information.

1-888-994-2663 (toll free)

1-231-946-8410 (International)

Standard parts could be as low as a 2-4 weeks. Custom features may change lead time.

Yes, please reach out to our Application Engineers for your specific needs.

PRODUCT DEVELOPMENT

The Cone Drive Product Development Laboratory is a state-of-the-art facility directly adjacent to our Traverse City, Michigan manufacturing location. The lab has the capacity to test a wide range of gear reducer products, for both Cone Drive products as well as those manufactured by other companies. The lab includes capability to run a wide variety of tests including load testing for evaluating reducer performance and operating efficiency.

TEST + CONTROL

PRODUCT MEASUREMENT

- Six product testing stands

- Servo cyclic control

- Simulated inertial loading

- Constant torque/load

- Durability/validation

- Accelerated life test

- Lubricant evaluation

- Static loading & stiffness

- Displacement & motion

- Torque

- Thermal

- Efficiency

- Vibration

- Basic noise

- Transmission accuracy