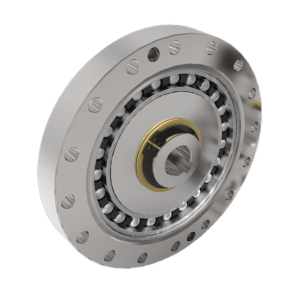

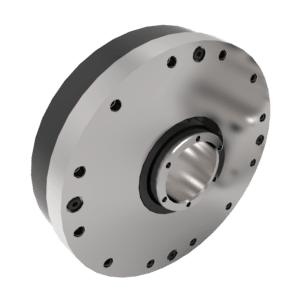

Cone Drive Harmonic Solutions®

Ultimate Precision

Cone Drive’s harmonic gearing is zero to low backlash by design. It provides high transmission accuracy and can support a high ratio reduction in a single stage with low inertia. The highly accurate, torque dense design makes harmonic gears the perfect solution for ultimate precision motion control applications.

We manufacture a wide range of strain wave gearing options in our line of Cone Drive Harmonic Solutions®.

Key Features

- Ring, Cup, and Hat Styles Available

- Component Sets and Gearheads

- Low to Zero Backlash

- High Transmission Accuracy

- Customizations Available Upon Request

- Manufactured and Assembled in Controlled Environment

- Competitive Lead Times

- 1 Year Warranty

HARMONIC GEARING SPECIFICATIONS

- Sizes: 11 thru 32

- Ratio: 50:1 thru 160:1

- Nominal Backlash: < 1 mRad

- Continuous Output Torque: < 172 Nm

- Peak Output Torque: < 824 Nm

- Standard Input Options: Keyed or set screws (including Oldman style coupling)

- Custom Input Options: Throughbore, solid input, dowel pins, tapped holes, piloted stepper/servo motor ready, special materials and coatings

- Configurations: Component gearset or gearhead, sealed, throughbore, lightweight, and other options available

Harmonic Gearing FAQ's

Traverse City, MI, USA

Please contact our Customer Service team with your selected style, size, ratio, and quantity.

1-888-994-2663 (toll free)

1-231-946-8410 (International)

2 – 4 weeks

The expected life for a standard unit varies by style, size, and ratio.

Please contact our Customer Service team for additional information.

1-888-994-2663 (toll free)

1-231-946-8410 (International)

Standard parts could be as low as a 2-4 weeks. Custom features may change lead time.

Yes, please reach out to our Application Engineers for your specific needs.

PRODUCT DEVELOPMENT

The Cone Drive Product Development Laboratory is a state-of-the-art facility directly adjacent to our Traverse City, Michigan manufacturing location. The lab has the capacity to test a wide range of gear reducer products, for both Cone Drive products as well as those manufactured by other companies. The lab includes capability to run a wide variety of tests including load testing for evaluating reducer performance and operating efficiency.

TEST + CONTROL

PRODUCT MEASUREMENT

- Six product testing stands

- Servo cyclic control

- Simulated inertial loading

- Constant torque/load

- Durability/validation

- Accelerated life test

- Lubricant evaluation

- Static loading & stiffness

- Displacement & motion

- Torque

- Thermal

- Efficiency

- Vibration

- Basic noise

- Transmission accuracy