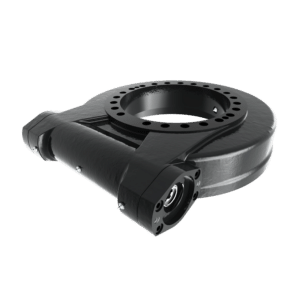

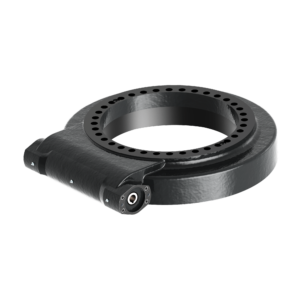

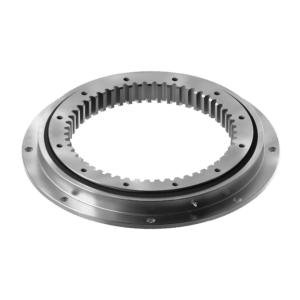

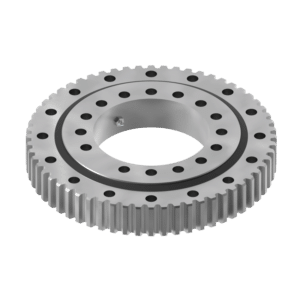

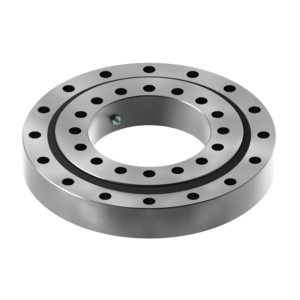

SLEWING BEARINGS AND DRIVES

Slew drives and slew bearings are designed to handle the heavy tilting, radial, and axial loads required by some industrial applications.

Slew bearings and drives are low profile to provide a high rotational capacity relative to size. Slewing technology is utilized across various industries ranging from heavy-duty construction to robotics and automation where the smooth rotation of heavy loads is critical.

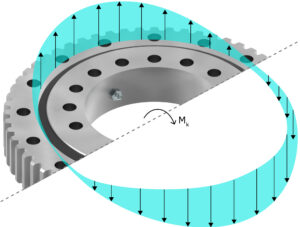

TILTING MOMENT

The tilting moment is the force multiplied by the distance from that force to the center of the slewing ring.

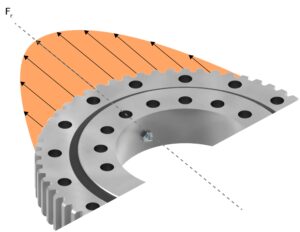

RADIAL LOAD

The radial load is the force perpendicular to the slewing ring axis.

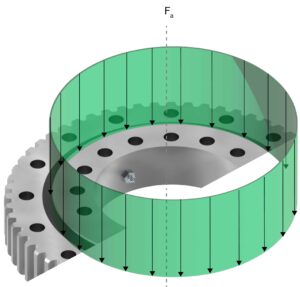

AXIAL LOAD

The axial load is the force parallel to the slewing ring axis.

HOLDING TORQUE

The holding torque is the maximum static torque that the unit can hold without damage to the drive.

SELF-LOCKING

Self-locking is the ability of the drive to resist rotation when holding torque is applied to the bearing.

Slewing FAQ's

Yes, a hand wheel or hand drill can be used to rotate the drive via the hex on the worm.

W-Series: 3 rpm max output speed; S-Series: 1 rpm max output speed

Yes, additional corrosion protection options are available. Please contact ae@conedrive.com for more information.

Typical slew drive efficiency is about 30%.

Worm and raceway of slew drives should be greased per the IOM

Yes, when mounting the slew drive horizontally, it is always recommended to mount the drive with the housing on top and seals on bottom, when possible. When mounting vertically, it is recommended to mount in the worm over orientation

Yes, however a WEA or WEB version is recommended when mounting in this orientation for additional corrosion protection. Please contact ae@conedrive.com for more information.