10 Uses of Cycloidal Gears in Engineering

Cycloidal gears are suitable for applications that require high gear reduction ratios, low friction, and strong wear resistance. As such, they are a great choice for motion control applications. With their unique geometry, cycloidal gears have found their place in numerous industries where precision, durability, and efficiency are important.

What is a cycloidal drive, and how does it work?

A cycloidal drive is a type of gear mechanism that uses cycloidal curves in its design. Unlike traditional involute gears, which rely on a constant pressure angle, cycloidal gears use a curve generated by the path of a point on a circle rolling along a straight line. The resulting profile creates gears with teeth that are highly durable, efficient, and able to withstand heavy loads. Cycloidal drives are most commonly used in systems where high reduction ratios, low noise, and durability are essential.

Which industries are cycloidal drives used most in?

Cycloidal drives are used in a variety of engineering and industrial applications, particularly where precision and efficiency are essential.

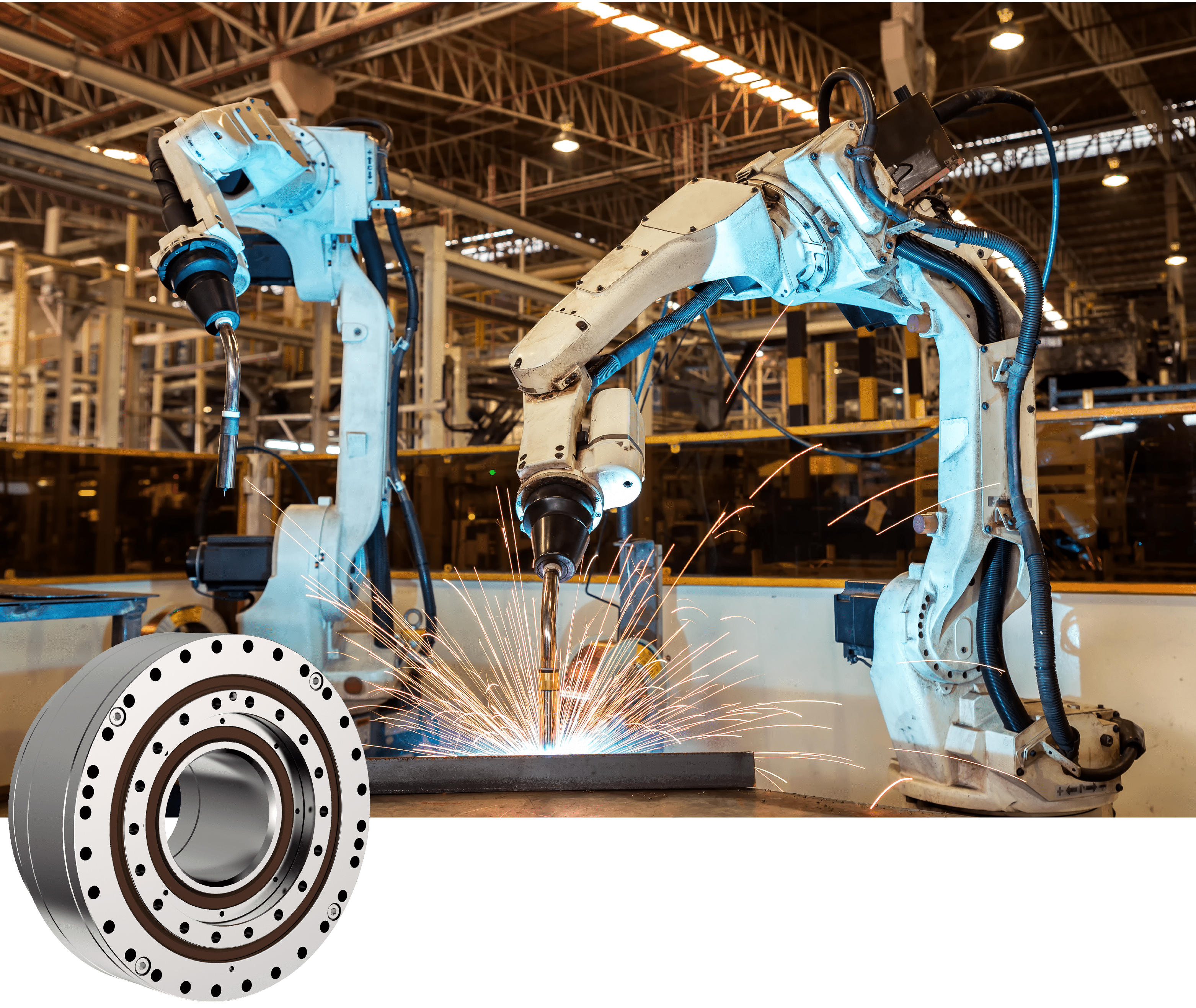

1. Robotics

In robotics, cycloidal drives are widely used due to their ability to handle high torque with minimal backlash. Robotics applications require precision, smooth motion, and reliability, which are all characteristics provided by cycloidal gears. They are used in robotic arms, actuators, and other motion control systems where compactness and high performance gear reductions are required.

2. Automotive Industry

The automotive industry utilizes cycloidal drives in electric vehicle (EV) transmissions, differential drives, and steering systems. Their ability to reduce high speed rotation from the motor into the desired speed and torque makes them ideal for applications in powertrains in EVs. Cycloidal gears also find use in power steering systems and automated manufacturing processes.

3. Aerospace and Defense

In aerospace, cycloidal drives are used in landing gear systems, actuators, and positioning systems. These drives are valued for their low maintenance needs and ability to operate under extreme conditions, such as high loads and high speeds. Their compact nature and durability are well suited to military and aerospace vehicles, including drones, satellites, and fighter jets.

4. Conveyor Systems

Cycloidal gears are commonly used in conveyor systems in industries such as manufacturing, packaging, and food processing. These gears are designed to handle high loads, which makes them suitable for moving heavy materials. They are often used in the reduction gearboxes of conveyor motors, offering smooth, efficient operation with minimal maintenance requirements.

5. Mining and Excavation

In mining equipment like drills, diggers, and excavation machines, cycloidal drives are used to transmit large amounts of torque at low speeds. The robustness and high torque to weight ratio of cycloidal gears make them perfect for handling the harsh and demanding conditions typically found in mining operations.

6. Wind Turbines

Wind turbines rely on cycloidal drives in some configurations to help convert wind energy into electrical energy. Cycloidal gears in the gearboxes of wind turbines reduce the rotational speed of the rotor to a level suitable for generating electricity. These drives are especially advantageous in offshore and large scale wind farms, which require reliability and durability.

7. CNC Machines

Computer Numerical Control (CNC) machines, which are used in the precise cutting, shaping, and manufacturing of parts, also make use of cycloidal drives in their motion control systems. The precision and accuracy of cycloidal gears allow for smooth and controlled movements, ensuring high quality machining and the ability to handle complex tasks without skipping or jerking.

8. Elevators and Lifts

Cycloidal drives are used in some elevator and lift systems due to their ability to provide smooth and quiet operation. The high torque capability and reduced vibration make them ideal for use in vertical transportation systems, especially in large buildings or places requiring frequent usage, such as hospitals and commercial facilities.

9. Printing Presses

In printing presses, cycloidal gears are used in the drive systems to handle the high speed, high torque demands of printing operations. These gears offer reliability and efficiency, even when exposed to the heavy loads and continuous use that printing presses experience. The smooth operation reduces noise and vibration, which is crucial in maintaining print quality.

10. Industrial Automation

Cycloidal drives play a significant role in industrial automation, where they are used in automated machinery, robotic arms, and assembly lines. The efficiency and robustness of cycloidal gears make them ideal for continuous operation in automated systems, where maintaining consistent speed and torque is necessary for precision and throughput.

What are the advantages of cycloidal drives?

Cycloidal drives offer several benefits that make them a preferred choice in many engineering applications.

- High Torque Capacity – Cycloidal gears are known for their ability to transmit high torque with minimal stress on the gear teeth. The rolling contact between the gears reduces the risk of wear and tear, enabling them to handle significant loads without failure. This makes them ideal for heavy duty applications in industries such as mining and automotive.

- Compact Design – Cycloidal gears offer high gear reduction ratios without the need for large, bulky gear sets. The compact nature of cycloidal drives allows for space savings in machinery, making them ideal for applications where size and weight constraints are a concern, such as in robotics and aerospace.

- Zero Backlash – The design of cycloidal gears results in reduced backlash, which is critical in applications requiring high precision. Low backlash ensures that the gears engage smoothly without jerking or skipping, which is particularly beneficial in robotics, CNC machines, and other automated systems.

- Durability and Longevity – Cycloidal gears have excellent wear resistance due to the smooth, rolling motion between the teeth. This reduces friction, leading to less heat generation and increased longevity compared to traditional gears. Their durability is a major advantage in industries with heavy machinery or extreme operational conditions, such as mining and wind turbines.

- Reduced Noise and Vibration – Cycloidal drives operate more quietly than many other gear types. The rolling contact between the gears minimizes vibrations and noise, which is especially beneficial in applications where noise reduction is important, such as in elevators, printing presses, and CNC machines.

Are there any cost implications when choosing cycloidal over other drives?

When choosing cycloidal drives over other types, cost is an important factor to consider. While cycloidal gears are generally more expensive to manufacture, they can offer significant savings over time due to their durability, reduced maintenance needs, and higher efficiency. In applications that require high torque, precision, and reliability, the initial investment in cycloidal drives can be justified by their longer lifespan and lower long term operating costs.

However, in applications where cost is a primary concern, such as in low torque systems or where the gear mechanism is not under heavy load, traditional gear systems may be more cost effective. In these cases, the benefits of cycloidal gears may not outweigh the additional costs.

Cone Drive Cycloidal Technology

From component sets to fully integrated actuators and mobile platform drives, these cycloidal products are engineered to perform in demanding robotic and automation environments.

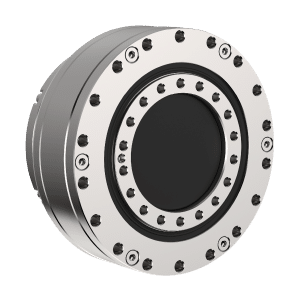

Spinea’s TwinSpin® cycloidal gear series offers a versatile range of high-precision, high-torque reducers designed for demanding motion control applications.

Spinea’s DriveSpin® series offers a comprehensive lineup of high-performance cycloidal servo actuators designed for dynamic motion control in robotics, automation, and precision equipment.

Spinea’s MoveSpin® series is a complete family of cycloidal-based traction and steering units purpose-built for autonomous mobile robots (AMRs) and automated guided vehicles (AGVs).