Precision Steering. Compact Integration. Maximum Control.

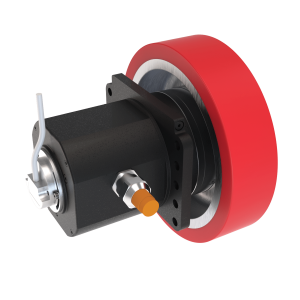

Spinea’s MoveSpin® series is a complete family of cycloidal-based traction and steering units purpose-built for autonomous mobile robots (AMRs) and automated guided vehicles (AGVs). From the ultra-low-profile MS 140-500 and fully rotating MS 160-500, to heavy-duty differential units like the MS 200-500 and compact MS 200-060, the lineup supports a wide range of platform sizes and payload requirements. The MS 160-500 DD provides designers with added flexibility for customized steering architectures.

Ultra-Low Profile Design

Integrated Traction and Steering

Advanced Sensor Integration

Integrated Traction and Steering

Fully Rotating Platform

Advanced Sensor Integration

High Load Capacity

Electronic Differential Steering Ready

Compact and Robust Design

Compact and Lightweight Design

Optimized for High-Speed Operation

Low-Maintenance Architecture

Compact, Space-Optimized Design

Minimal Turning Radius

Customizable Steering Integraiton

PRECISION • MOTION CONTROL • TECHNOLOGY

We design and manufacture worm gears, worm gearboxes, slew bearings, slew drives, harmonic, and cycloidal gearing. With a history of gearbox manufacturing that spans nearly 100 years, we are a world leader in precision motion control technology. With Cone Drive you can always find the right solution for your application with the highest quality products and the lead times you require.

FAQ's

Traverse City, MI, USA

Please contact our Customer Service team with your selected style, size, ratio, and quantity.

1-888-994-2663 (toll free)

1-231-946-8410 (International)

2 – 4 weeks

The expected life for a standard unit varies by style, size, and ratio.

Please contact our Customer Service team for additional information.

1-888-994-2663 (toll free)

1-231-946-8410 (International)

Standard parts could be as low as a 2-4 weeks. Custom features may change lead time.

Yes, please reach out to our Application Engineers for your specific needs.

PRODUCT DEVELOPMENT

The Cone Drive Product Development Laboratory is a state-of-the-art facility directly adjacent to our Traverse City, Michigan manufacturing location. The lab has the capacity to test a wide range of gear reducer products, for both Cone Drive products as well as those manufactured by other companies. The lab includes capability to run a wide variety of tests including load testing for evaluating reducer performance and operating efficiency.

TEST + CONTROL

PRODUCT MEASUREMENT

- Six product testing stands

- Servo cyclic control

- Simulated inertial loading

- Constant torque/load

- Durability/validation

- Accelerated life test

- Lubricant evaluation

- Static loading & stiffness

- Displacement & motion

- Torque

- Thermal

- Efficiency

- Vibration

- Basic noise

- Transmission accuracy