Metalworking automation

Cone Drive powers modern fabrication with high-torque rotation and compact precision—driving performance in welding, positioning, and assembly.

Powering Precision in Every Rotation

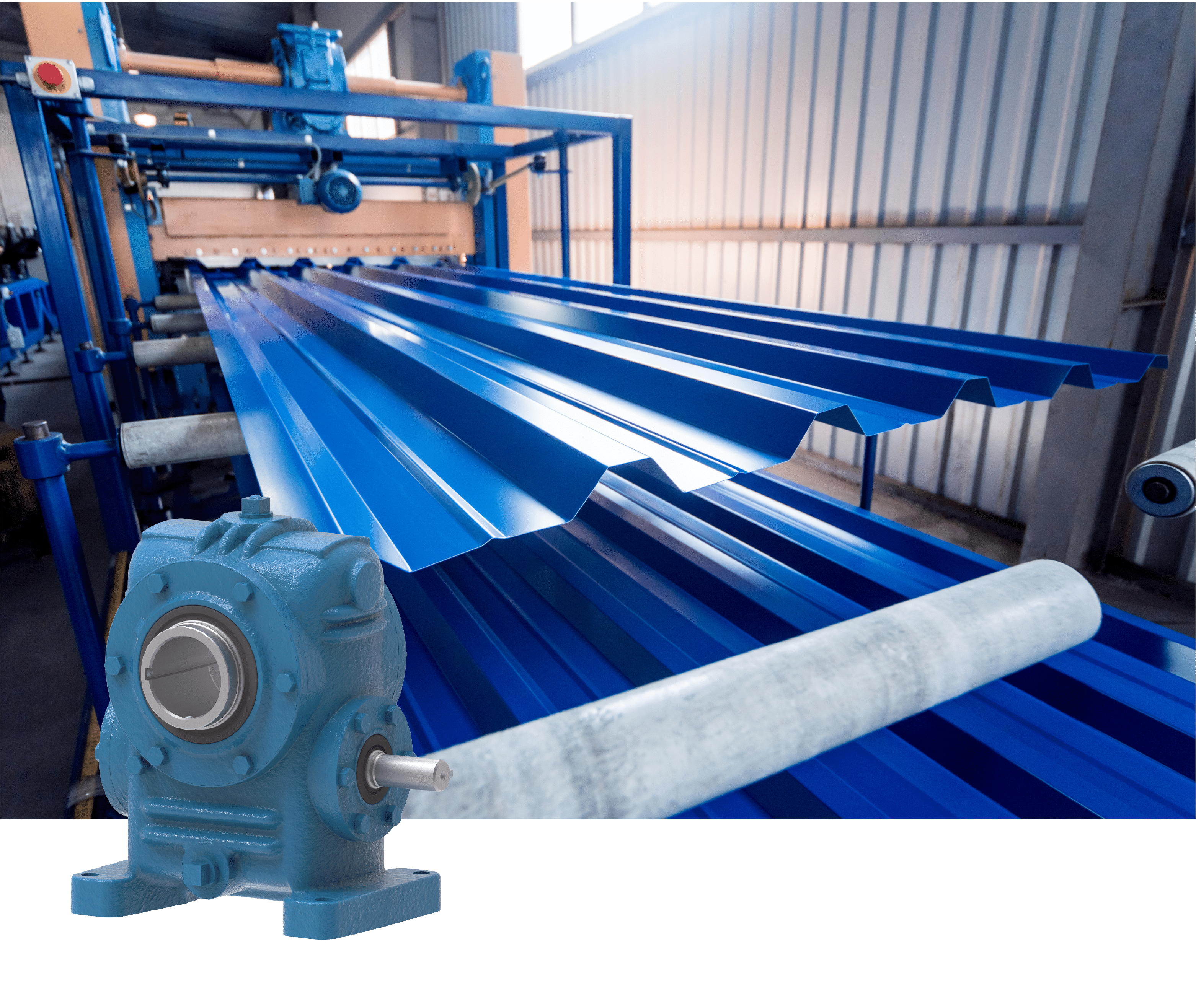

The metalworking industry runs on precision, strength, and control—from cutting and forming to welding and assembly. As automation grows, gear technologies are essential to both manual and automated operations. Cone Drive’s worm, harmonic, cycloidal, and slewing solutions deliver high torque, smooth motion, and compact footprints. From powering cutting heads and roll formers to rotating heavy weldments on welding positioners, Cone Drive keeps fabrication moving with strength and precision.

In Action

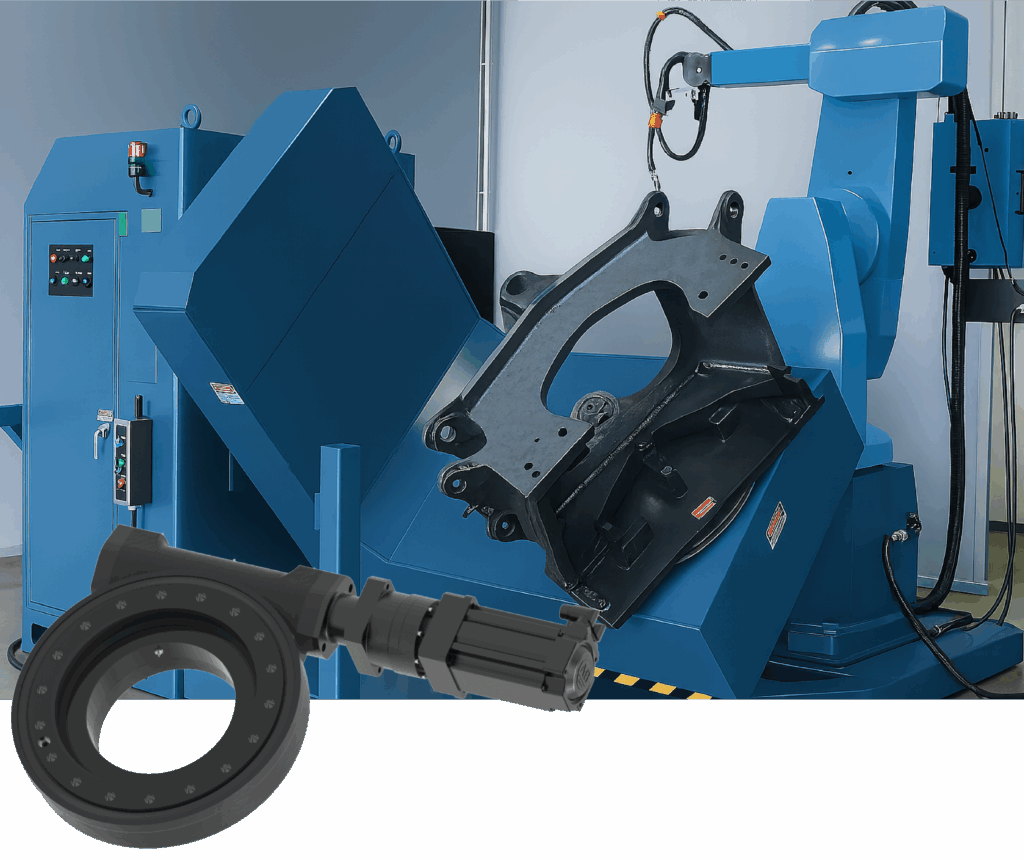

Welding Positioners

Rotary Welding Tables

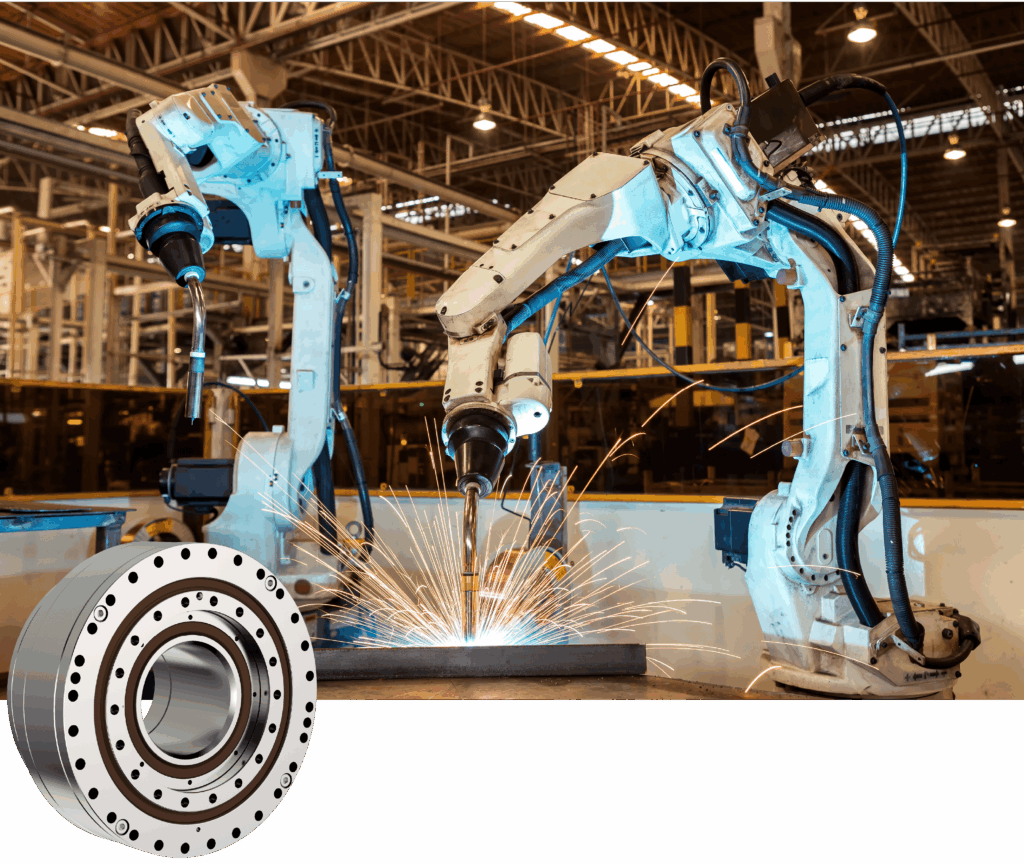

Robotic Welding Arms

Indexing Turntables

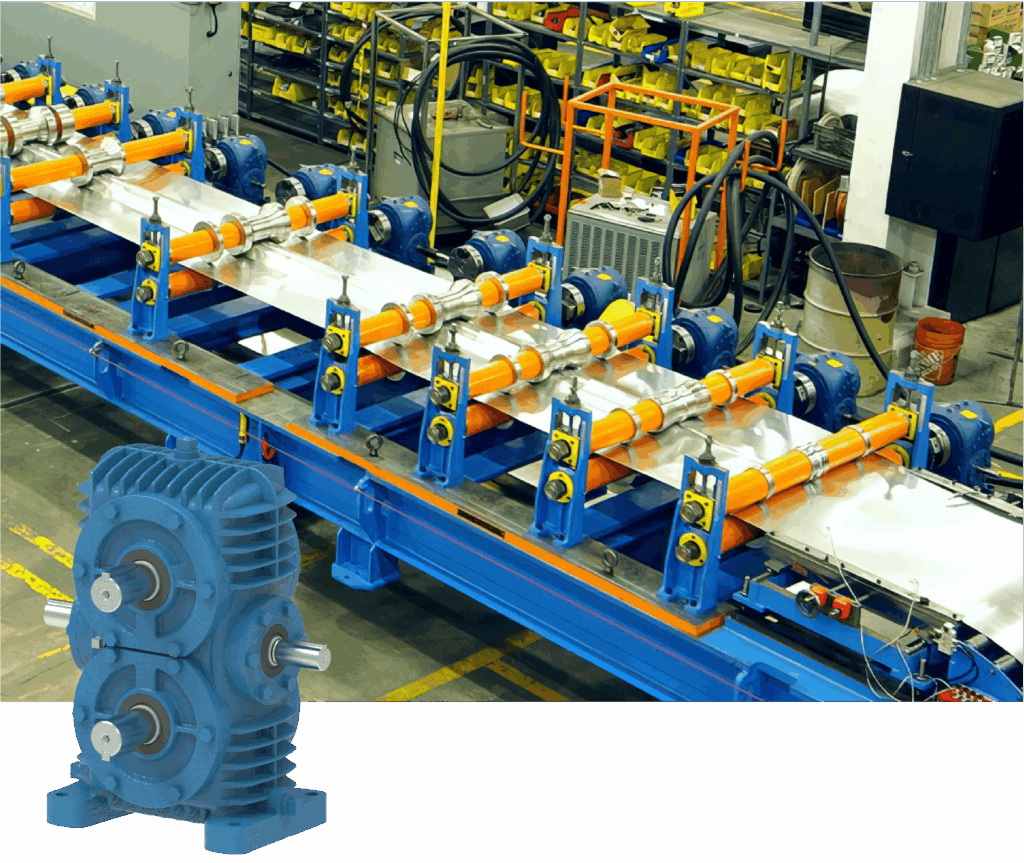

Roll Forming Equipment

Sheet Metal Bending

Multi-Axis Tool Manipulators

Pipe Welding Rollers

Manual Plasma Torch Positioning

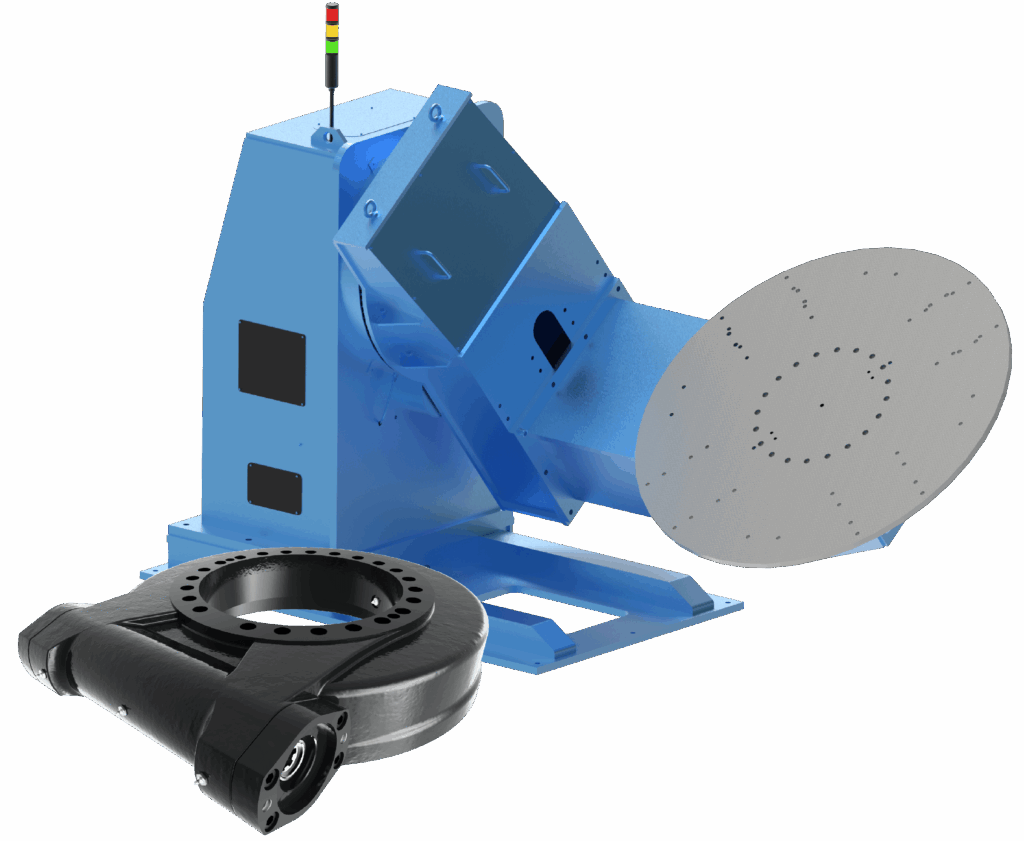

NEW Electric Motor-Driven Double Reduction Slew Drive — Clean, Efficient Power for Demanding Applications

Our Competitive Advantage

Leading Performance

Recognized for our accuracy and precision

Short Lead Times

We ship in days; not weeks or months

Highest Torque/Power Density

Smallest form factor in the industry

Highly Customizable Solutions

We can engineer a solution for your unique application

Superior Quality

With over 100 years in the industry, we offer robust and reliable solutions

Global Presence, Local Support

Where it’s need, when it’s needed

Four Technologies. One Trusted Source.

Harmonic Strain Wave Gearing

Designed for compact, high-precision motion control, Cone Drive’s harmonic solutions offer drop-in compatibility with competitors and full customization in cup, hat, and ring styles—including lightweight and “F-style” bolt patterns.

TwinSpin® Precision Cycloidal Gearing

For demanding applications requiring zero backlash and high torque in a compact footprint, Spinea’s cycloidal gear units deliver superior torsional stiffness, load capacity, and integrated design flexibility.

Slewing Drives & Bearings

Cone Drive’s slewing drives feature high-ratio gearing in a compact, ready-to-install housing, optimized for weight and performance. Cone Drive’s slewing bearings can handle the axial, radial, and tilting moments for the most challenging applications – select sizes and styles available from stock.

Double Enveloping Worm Gearing

Precision-engineered and made in the USA, Cone Drive’s double enveloping worm gears deliver smooth, high-torque transmission with low or zero backlash, customizable for NEMA and servo applications—including IP69K-rated options.

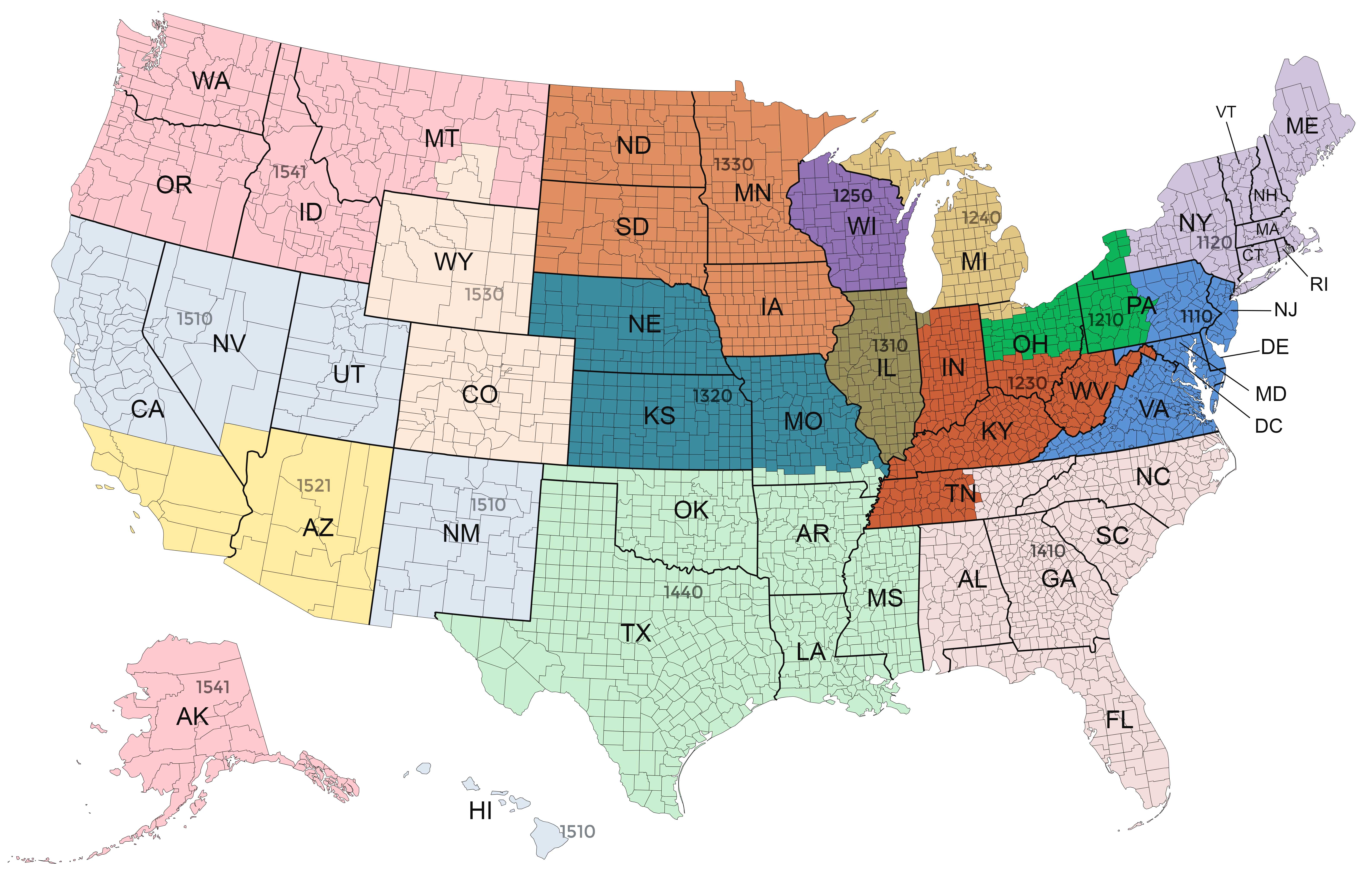

A Global System of Support

United States

Canada

Desmond O'Keefe

dokeefe@conedrive.com

+1.437.328.2063

Mexico and Central America

Jamie Prewitt

jprewitt@conedrive.com

+1.214.883.4457

South America

Jamie Prewitt

jprewitt@conedrive.com

+1.214.883.4457

Europe

Spinea

info@spinea.com

+421.51.77.00.156

Africa

Mark Walker

mwalker@conedrive.com

+1.330.604.0363

Asia

sales@conedrive.com.cn

+86.510.86366206

Australia

Mark Walker

mwalker@conedrive.com

+1.330.604.0363

PRODUCT DEVELOPMENT

The Cone Drive Product Development Laboratory is a state-of-the-art facility directly adjacent to our Traverse City, Michigan manufacturing location. The lab has the capacity to test a wide range of gear reducer products, for both Cone Drive products as well as those manufactured by other companies. The lab includes capability to run a wide variety of tests including load testing for evaluating reducer performance and operating efficiency.

TEST + CONTROL

PRODUCT MEASUREMENT

- Six product testing stands

- Servo cyclic control

- Simulated inertial loading

- Constant torque/load

- Durability/validation

- Accelerated life test

- Lubricant evaluation

- Static loading & stiffness

- Displacement & motion

- Torque

- Thermal

- Efficiency

- Vibration

- Basic noise

- Transmission accuracy