Humanoid Robots

Our U.S.-made harmonic strain wave gearing, paired with Spinea’s proven cycloidal technology, equips humanoid robots with precision, durability, and the performance needed to shape the future.

Where Human Agility Meets Gearbox Precision

Cone Drive gearing is built for the demands of humanoid robots—delivering smooth, lifelike motion where precision and reliability matter most. Our U.S.-made harmonic strain wave gearing drives compact, backlash-free joints like hips, knees, and wrists, while our cycloidal reducers provide the stiffness and durability needed for high-load axes such as waist and shoulders. Backed by over a century of engineering expertise, Cone Drive helps robot developers create machines that move with strength, safety, and humanlike agility.

In Action

Hip Pitch/Roll Joints

Knee Joints

Ankle Joints

Shoulder Pitch/Roll Joints

Wrist Joints

Waist/Yaw Axis

Hip Yaw Joint

Shoulder Yaw Joint

Pelvis/Lower Back Modules

• Compact and lightweight for tight humanoid joint spaces

• Zero backlash for smooth, precise, humanlike motion

• Quiet and efficient, ideal for collaborative environments

• Durable and reliable, ensuring long service life

• U.S.-made for quality and secure supply chains

• High torque and load capacity for hips, knees, and core joints

• Exceptional rigidity for balance and stability

• Compact, integrated design simplifies actuator assembly

• Zero backlash, consistent torque under load

• Proven performance in robotics and automation

Combined Value

• Complete motion solution

• Scalable across all humanoid joints

• Backed by Timken expertise

Our Competitive Advantage

Leading Performance

Recognized for our accuracy and precision

Short Lead Times

We ship in days; not weeks or months

Highest Torque/Power Density

Smallest form factor in the industry

Highly Customizable Solutions

We can engineer a solution for your unique application

Superior Quality

With over 100 years in the industry, we offer robust and reliable solutions

Global Presence, Local Support

Where it’s need, when it’s needed

Four Technologies. One Trusted Source.

Harmonic Strain Wave Gearing

Designed for compact, high-precision motion control, Cone Drive’s harmonic solutions offer drop-in compatibility with competitors and full customization in cup, hat, and ring styles—including lightweight and “F-style” bolt patterns.

TwinSpin® Precision Cycloidal Gearing

For demanding applications requiring zero backlash and high torque in a compact footprint, Spinea’s cycloidal gear units deliver superior torsional stiffness, load capacity, and integrated design flexibility.

Slewing Drives & Bearings

Cone Drive’s slewing drives feature high-ratio gearing in a compact, ready-to-install housing, optimized for weight and performance. Cone Drive’s slewing bearings can handle the axial, radial, and tilting moments for the most challenging applications – select sizes and styles available from stock.

Double Enveloping Worm Gearing

Precision-engineered and made in the USA, Cone Drive’s double enveloping worm gears deliver smooth, high-torque transmission with low or zero backlash, customizable for NEMA and servo applications—including IP69K-rated options.

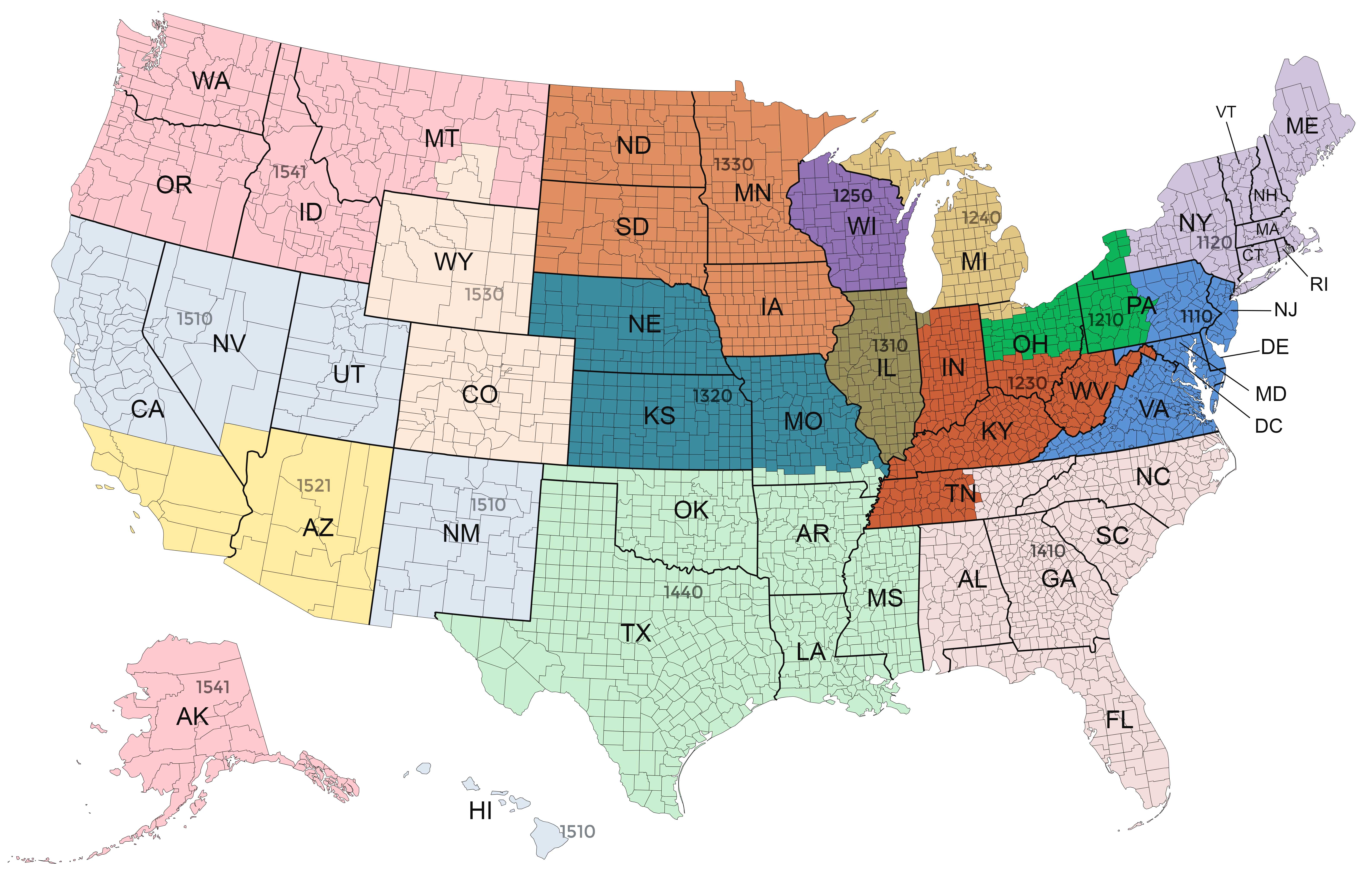

A Global System of Support

United States

Canada

Desmond O'Keefe

dokeefe@conedrive.com

+1.437.328.2063

Mexico and Central America

Jamie Prewitt

jprewitt@conedrive.com

+1.214.883.4457

South America

Jamie Prewitt

jprewitt@conedrive.com

+1.214.883.4457

Europe

Spinea

info@spinea.com

+421.51.77.00.156

Africa

Mark Walker

mwalker@conedrive.com

+1.330.604.0363

Asia

sales@conedrive.com.cn

+86.510.86366206

Australia

Mark Walker

mwalker@conedrive.com

+1.330.604.0363

PRODUCT DEVELOPMENT

The Cone Drive Product Development Laboratory is a state-of-the-art facility directly adjacent to our Traverse City, Michigan manufacturing location. The lab has the capacity to test a wide range of gear reducer products, for both Cone Drive products as well as those manufactured by other companies. The lab includes capability to run a wide variety of tests including load testing for evaluating reducer performance and operating efficiency.

TEST + CONTROL

PRODUCT MEASUREMENT

- Six product testing stands

- Servo cyclic control

- Simulated inertial loading

- Constant torque/load

- Durability/validation

- Accelerated life test

- Lubricant evaluation

- Static loading & stiffness

- Displacement & motion

- Torque

- Thermal

- Efficiency

- Vibration

- Basic noise

- Transmission accuracy