Double Reduction Slew Drive

Clean, Efficient Power

READY TO GET RID OF YOUR MESSY, HYDRAULIC SYSTEM?

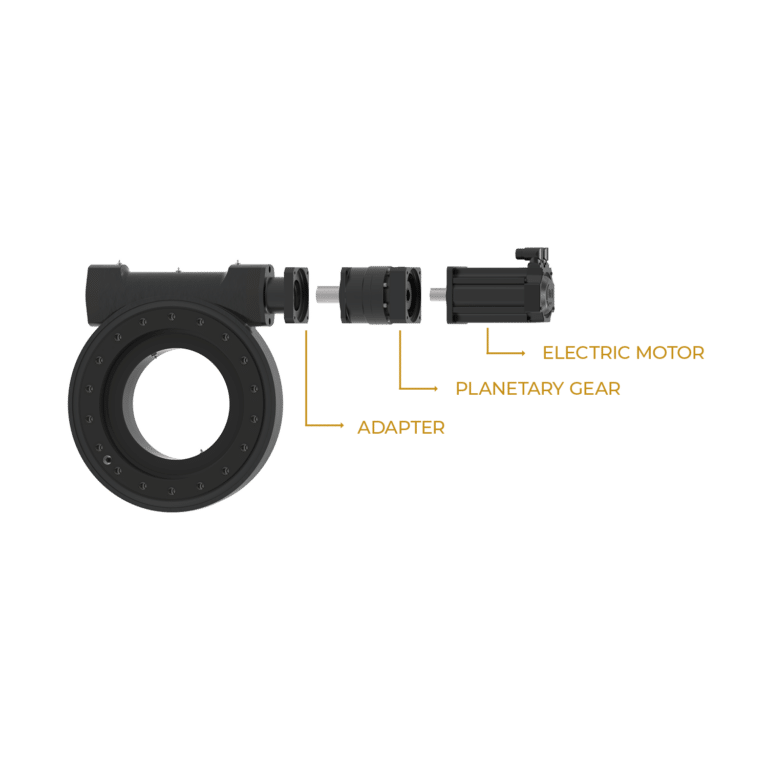

Cone Drive has you covered with our double reduction slew drives. When using an electric motor (Servo or NEMA) to power a slewing drive, it is recommended to install a planetary gear as the primary reducer. This combination offers superior control, ease of integration into your systems, energy efficiency, and reduced maintenance.

Cone Drive stocks a family of adapters and shafts for the most common primary gearboxes, ensuring a quick turnaround and a one-stop solution for your double reduction slew drive needs.

Key Features

- Designed for Electric Motor Applications

- Clean Setup

- Low Profile

- Superior Control

- Ease of Integration

- Energy Efficient

- Reduced Maintenance

- Adapters in Stock

DOUBLE REDUCTION SLEW DRIVE SPECIFICATIONS

- Available for Series S Sizes: 9 thru 25 in

- Available for Series W Sizes: 7 thru 28 in

- Adapter: SAE6B Spline

- Housing Options: Open, closed, high strength

- Output Torque: < 44,220 lb-ft

- Holding Torque: < 116,535 lb-ft

- Overturning Moment: < 228,644 lb-ft

- Sealed Drive Available

Contact us for application engineering support on selecting a gearset tailored to your application.

Single page product summary sheet.

Why Choose Cone Drive as Your Slew Drive and Slew Bearing Manufacturer

- We provide custom slew drive and slew bearing solutions

- We can provide on-site slew gearbox installation

- All of our slew drives and slew bearings come with dedicated engineering support

Optimized Design for Enhanced Performance

At Cone Drive, we understand the importance of weight and performance optimization. That’s why our low-profile designs are engineered to be lightweight, without sacrificing performance.

Our slewing bearing’s large, open inner race diameter provides system design flexibility, allowing you to easily incorporate them into your current applications. Furthermore, our bearings can be seamlessly integrated into a slewing drive, taking advantage of Cone Drive’s extensive gearing expertise.

FAQ's

Yes, a hand wheel or hand drill can be used to rotate the drive via the hex on the worm.

W-Series: 3 rpm max output speed; S-Series: 1 rpm max output speed

Yes, additional corrosion protection options are available. Please contact ae@conedrive.com for more information.

Typical slew drive efficiency is about 30%.

Worm and raceway of slew drives should be greased per the IOM

Yes, when mounting the slew drive horizontally, it is always recommended to mount the drive with the housing on top and seals on bottom, when possible. When mounting vertically, it is recommended to mount in the worm over orientation

Yes, however a WEA or WEB version is recommended when mounting in this orientation for additional corrosion protection. Please contact ae@conedrive.com for more information.

PRODUCT DEVELOPMENT

The Cone Drive Product Development Laboratory is a state-of-the-art facility directly adjacent to our Traverse City, Michigan manufacturing location. The lab has the capacity to test a wide range of gear reducer products, for both Cone Drive products as well as those manufactured by other companies. The lab includes capability to run a wide variety of tests including load testing for evaluating reducer performance and operating efficiency.

TEST + CONTROL

PRODUCT MEASUREMENT

- Six product testing stands

- Servo cyclic control

- Simulated inertial loading

- Constant torque/load

- Durability/validation

- Accelerated life test

- Lubricant evaluation

- Static loading & stiffness

- Displacement & motion

- Torque

- Thermal

- Efficiency

- Vibration

- Basic noise

- Transmission accuracy