UNLEASH PRECISION AND POWER

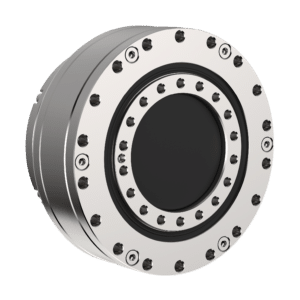

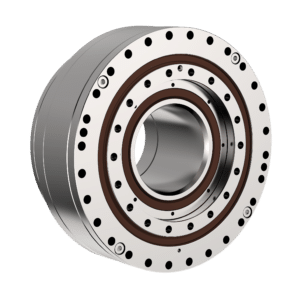

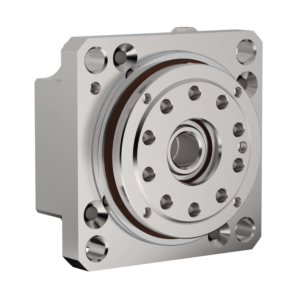

Cycloidal gearing offers high efficiency and torque capacity, distributing stress evenly across multiple contact points. Its compact design allows for high torque output in space-constrained environments with smooth, low-backlash operation. Cycloidal gearing’s robust construction ensures durability, making it ideal for precision applications like robotics and machinery.

Improved Torque and Overload Capacity

Low Backlash

Modular & Customizable Design

Cylinder Shaped Housing

Zero Backlash

High Torsional and Tilting Stiffness

Cylinder Shaped Housing

High Capacity Radial and Axial Bearings

Modular Design

FAQ's

Transmission ratios less than 30:1 can be discussed if requested. Ratios that are not offered as a standard bear higher risk of transmission inaccuracies. Consult technical and delivery conditions with the sales department or our local sales representative.

TwinSpin® runs extremely smoothly. Reference noise measurements of the reduction gear mounted upon a servomotor are available on request.

Reduction gears are preferably intended for duty cycles S3-S8, i.e. output speed in applications is variable in both directions. The S1 duty cycle should be consulted with the manufacturer, but it should not exceed the ambient temperature of 25°C by 40°C.

There is an axial clearance at the input shaft of the reduction gear that allows heat dilatation. Please pay attention to the adjustment of clearance when interfacing the reduction gear with servomotor (see reference Cycloidal Catalog, Chapter 5).

Grease is used in the standard applications. Oil is only used in in special application requests demanding very low viscous friction, in high-speed applications, at special conditions and users´ preferences (e.g. extremely cold environment for radar applications).

The installation position may be vertical or horizontal. Upon request, the manufacturer will provide engineering support, including assembly drawings.

The nominal lifetime L10 means the time in hours when up to 10 % of a batch fails due to material fatigue.

The rated torque is calculated value of the loading constant torque at the nominal constant input speed of the input shaft for the duty cycle when the calculated nominal lifetime is L10 = 6,000 hours and the duty factor ED = 1 (100 %).

Yes. We are able to provide you with necessary technical support. Regarding the flange interfacing, we have a database of typical connecting couplings and interface flanges drawings. We are able to prepare the assembly and detail drawings for customers, if they specify the type and size of motor. Upon request we are also able to manufacture the motor flange and coupling.

There are two options. The first one is no clearance and prestressed in both directions as necessary. The second one is axial and radial clearance of up to 10 microns.

TwinSpin® is a zero backlash reduction gear because there is no reversal clearance between the trochoid teeth of the gear wheels and the cylindrical rollers of the hollow gear wheels in the reduction gear case. This is reached by high-precision manufacturing of components and careful pairing during the assembly.

No. Thanks to very good efficiency there is no self-locking effect. For back-driving torque values see Cycloidal Catalog, Chapter 3.13.

The nominal lifetime is limited by the roller bearing between the eccentric shaft and the gearwheels.

PRODUCT DEVELOPMENT

The Cone Drive Product Development Laboratory is a state-of-the-art facility directly adjacent to our Traverse City, Michigan manufacturing location. The lab has the capacity to test a wide range of gear reducer products, for both Cone Drive products as well as those manufactured by other companies. The lab includes capability to run a wide variety of tests including load testing for evaluating reducer performance and operating efficiency.

TEST + CONTROL

PRODUCT MEASUREMENT

- Six product testing stands

- Servo cyclic control

- Simulated inertial loading

- Constant torque/load

- Durability/validation

- Accelerated life test

- Lubricant evaluation

- Static loading & stiffness

- Displacement & motion

- Torque

- Thermal

- Efficiency

- Vibration

- Basic noise

- Transmission accuracy