How are slew drives used in solar panels

The sun is a great source of energy and solar power electricity generation has been improving greatly in efficiency over its lifetime. Slew drives are one piece of this improved efficiency.

Benefits of solar energy

Solar energy is one of the most abundant and renewable energy sources available. Solar panels can operate for decades with minimal maintenance. Once installed, they generate electricity with no fuel costs, reducing reliance on traditional power sources. Another major benefit of solar energy is its scalability. Solar panels can be used in small residential installations or large solar farms that power entire communities. With advancements in technology, efficiency rates have improved significantly, making it a viable energy option.

What is solar tracking?

Solar tracking is a method used to maximize the efficiency of solar panels by adjusting their position to follow the movement of the sun. Instead of remaining fixed at a single angle, solar trackers tilt and rotate panels throughout the day to capture the most sunlight possible. This helps to make the most out of the available sun allowing for increased energy production compared to stationary systems.

There are two main types of solar tracking systems: single axis and dual axis. Single axis trackers follow the sun’s movement from east to west, optimizing exposure throughout the day. Dual axis trackers also adjust for seasonal variations in the sun’s angle, further improving energy capture.

Why do solar trackers need slew drives?

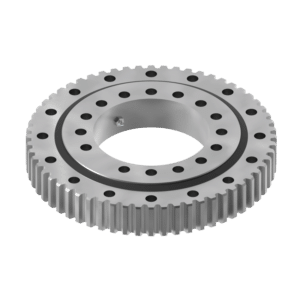

Slew drives are essential components in solar tracking systems. They provide the necessary movement and positioning for solar panels to track the sun accurately. A slew drive is a compact, self-contained unit that combines a worm gear, housing, and bearings to enable smooth and controlled rotation.

Solar trackers require precise and reliable motion control, and slew drives offer this by providing rotational movement with high torque and minimal backlash. Without slew drives, solar trackers would struggle to maintain consistent and smooth motion, leading to reduced energy production.

Slew drives are also designed to withstand outdoor conditions, including wind, rain, and temperature variations. Their durable construction ensures long term performance, making them a critical component in solar tracking systems.

Why slew drives are perfect for solar tracking?

Slew drives are ideal for solar tracking because they provide efficient, reliable, and precise movement. Here are some reasons why slew drives are the perfect solution for solar tracking:

- High efficiency: Slew drives convert rotational movement into powerful and controlled motion, ensuring solar panels are always positioned for maximum energy capture.

- Durability: Built to endure harsh outdoor conditions, slew drives are resistant to extreme temperatures, moisture, and dust. This makes them ideal for long term use in solar tracking applications.

- Compact design: Slew drives take up minimal space while providing maximum power and efficiency. Their integrated design simplifies installation and maintenance.

- Precision and stability: Solar tracking requires accuracy to ensure panels follow the sun’s path effectively. Slew drives provide precise movement with minimal backlash, maintaining the correct alignment at all times.

- Low maintenance: Due to their enclosed design and high quality components, slew drives require minimal maintenance. This helps reduce operational costs and ensures continuous performance.

As solar energy continues to grow in popularity, the need for efficient tracking solutions becomes even more important. Slew drives offer the perfect combination of reliability, durability, and performance, making them a key component in modern solar tracking systems. With their ability to maximize energy production and reduce overall costs, slew drives play a significant role in the advancement of solar power technology.

Cone Drive Slew Technology

Cone Drive are recognised as experts in the field of motion control technology. Our slewing solutions are used in industrial applications that require heavy tilting, radial and axial loads. Our bearings and drives are used in industries ranging from heavy-duty construction to robotics and automation.