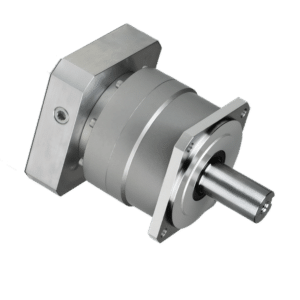

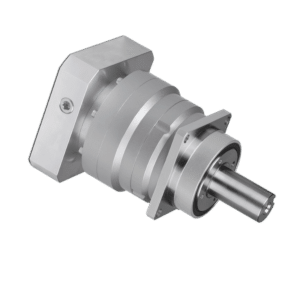

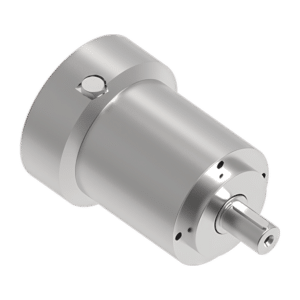

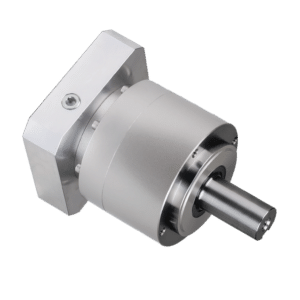

Planetary Gearing

Inline Precision

Cone Drive’s planetary gearing offers an inline solution to satisfy the most demanding automation application needs. The compact design and universal housing make planetary gearing ideal for multiple applications. The precision bearings and planetary gearing provides high torque density while maintaining positional performance.

Key Features

- Multiple Versions Available

- Quiet Operation

- Ratios up to 10:1 in a Single Stage

- Low Backlash

- High Efficiency

- Stainless Steel Available

- Competitive Interchanges Available

- Best in Class Lead Times

- 5 Year Warranty

PLANETARY GEARBOX SPECIFICATIONS

- Case Size: 50 thru 240

- Ratio: 3:1 thru 100:1

- Nominal Backlash: 3 – 14 arcmin

- Output Torque (ConstantSpeed): < 2,400 Nm

- Output Torque (Acceleration): < 3,700 Nm

- Input Shaft: Fits servo or stepper motors

- Output Shaft: Solid shaft (smooth or keyed)

- Lubricant: Factory filled with synthetic grease

- I.P. Rating: IP54, IP55, IP65, IP66

Build a gearbox based on gearbox model and specifications.

Single page product summary sheet.

Full product catalog.

PRODUCT DEVELOPMENT

The Cone Drive Product Development Laboratory is a state-of-the-art facility directly adjacent to our Traverse City, Michigan manufacturing location. The lab has the capacity to test a wide range of gear reducer products, for both Cone Drive products as well as those manufactured by other companies. The lab includes capability to run a wide variety of tests including load testing for evaluating reducer performance and operating efficiency.

TEST + CONTROL

PRODUCT MEASUREMENT

- Six product testing stands

- Servo cyclic control

- Simulated inertial loading

- Constant torque/load

- Durability/validation

- Accelerated life test

- Lubricant evaluation

- Static loading & stiffness

- Displacement & motion

- Torque

- Thermal

- Efficiency

- Vibration

- Basic noise

- Transmission accuracy