Solar Tracking

Cone Drive has a long history of developing custom solutions for both single-axis and dual-axis solar tracker drives. As a global solar drive manufacturer we have the experience and the reach to deliver highly effective solar solutions.

Satellite Communication Positioning

The rapid expansion of the Ka-band technology has driven the need for precision motion control tracking capabilities for Satellite + Antennae positioning systems. Our custom solutions address azimuth + elevation motion control capable of meeting the tightest specifications.

Key Features

- Gated Product Development Process

- Specification Development

- 3D & 2D Design

- Simulation, FEA

- Engineering Analysis, DFMEA

- Prototyping

- Custom Solar Tracker Test Design & Design Verification

- Custom Solar Drive Manufacturing

TRACKING & POSITIONING GEARBOX SPECIFICATIONS

| PRODUCT TYPE | DESCRIPTION | PRECISION LEVEL | OUTPUT TORQUE (Nm) | RATIOS |

|---|---|---|---|---|

| Solar Tracker Drive (TD) | Foot Mounted Elevation Drive | > 5.0 mRad | 150 - 145,000 | 5:1 - 85:1 |

| Solar Azimuth Drive (AD) | Gear/Output Flange Mounted Azimuth Drive | > 0.7 mRad | 150 - 15,000 | 5:1 - 85:1 |

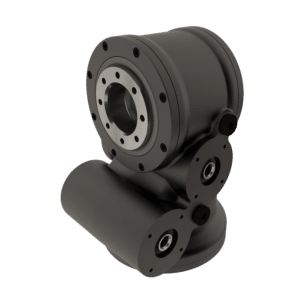

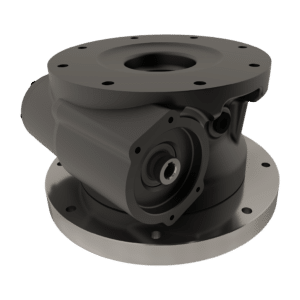

| Dual Axis Solar Drive (DD) | Gear/Output Flange Mounted Dual Axis Drive | > 0.7 mRad | 30 - 2,000 | 5:1 - 85:1 |

| Solar Slewing Drive (SE) | Housing Mounted Azimuth Slewing Drive | > 16.4 mRad | 240 - 158,300 | 61:1 - 150:1 |

| Vertical Solar Slewing Drive (VE) | Foot Mounted Elevation Slewing Drive | > 16.4 mRad | 240 - 105,800 | 30:1 - 125:1 |

| Dual Axis Solar Slewing Drive (WD) | Gear/Output Flange Mounted Dual Axis Drive | > 11.0 mRad | 400 - 2,000 | 28:1 - 62:1 |

PRODUCT DEVELOPMENT

The Cone Drive Product Development Laboratory is a state-of-the-art facility directly adjacent to our Traverse City, Michigan manufacturing location. The lab has the capacity to test a wide range of gear reducer products, for both Cone Drive products as well as those manufactured by other companies. The lab includes capability to run a wide variety of tests including load testing for evaluating reducer performance and operating efficiency.

TEST + CONTROL

PRODUCT MEASUREMENT

- Six product testing stands

- Servo cyclic control

- Simulated inertial loading

- Constant torque/load

- Durability/validation

- Accelerated life test

- Lubricant evaluation

- Static loading & stiffness

- Displacement & motion

- Torque

- Thermal

- Efficiency

- Vibration

- Basic noise

- Transmission accuracy