Built in Michigan. Trusted Worldwide.

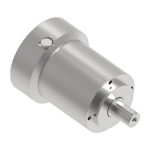

Cone Drive’s servo driven gearing products are adaptable to a wide variety of servo motor sizes.

Standard, low, and zero backlash options are available to meet the requirements of your most demanding precision applications.

If you require a motor adaptation that we currently do not have listed as standard, Cone Drive’s robust team of engineers can quickly crank out a design to mate up with most any servo motor on the market.

Cone Drive’s NEMA driven gearing products are adaptable to a wide variety of motor sizes.

In addition to gearboxes with an integrated motor adapter flange, Cone Drive also offers a reducer style that can be driven by a belt, chain, etc.

Cone Drive’s NEMA motor mount gearboxes are equipped with a non fretting quill design that makes motor removal a simple and quick task.

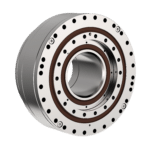

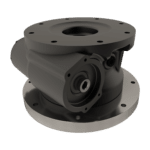

Cone Drive’s cup-style harmonic gearing solutions are designed for compact, high-torque applications requiring precise, zero-backlash motion control. In this configuration, the torque is transmitted through the closed (bottom) surface of the cup, providing a lightweight, space-efficient solution ideal for tight integration.

The CBC, CBCF-, CBC-L, CBG, and CBGF- series offer features such as integrated cross-roller bearings and industry-standard mounting interfaces—and are fully customizable to meet specific application and performance requirements.

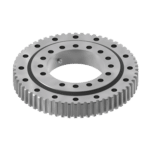

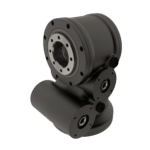

Cone Drive’s hat-style harmonic gearing solutions are built for high-precision, high-torque applications where smooth motion and robust load handling are essential. In this configuration, the torque is transmitted through the flanged brim of the hat, providing a stable and accessible interface for integration.

The HBC, HBCF-, HBG, HBGT-, and HBGHL series include options such as housed outputs, large hollow shafts, sealed designs, and integrated cross-roller bearings—making them ideal for robotics, automation, and demanding industrial environments. These solutions are fully customizable to meet unique space, torque, and performance requirements.

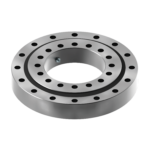

Cone Drive’s ring-style harmonic gearing solutions—RLC and RBC—are designed for applications requiring a compact, high-precision solution with flexible integration. In this configuration, the load is supported through the outer ring, with mounting typically done on the circular shaped ID Spline, allowing for seamless integration into rotating systems such as turntables or positioning platforms.

The RLC offers an ultra-compact design, while the RBC provides increased torque capacity in while maintaining a compact footprint. Both models are fully customizable to meet exact torque, ratio, and mounting interface requirements—making them ideal for robotics, automation, and space-constrained systems.

The Cone Drive Service Center specializes in double enveloping worm gears, helical/bevel industrial gearboxes, and planetary gear systems. We offer comprehensive services including reverse engineering, inspection, rebuilds, and repairs.

Equipped with a state-of-the-art FARO Edge portable CMM, our team ensures precise, high-quality results. We can retrofit and restore gearboxes of virtually any type or size—often enhancing performance beyond original specifications—by replacing existing gearing with our advanced Double Enveloping Worm Gear technology.

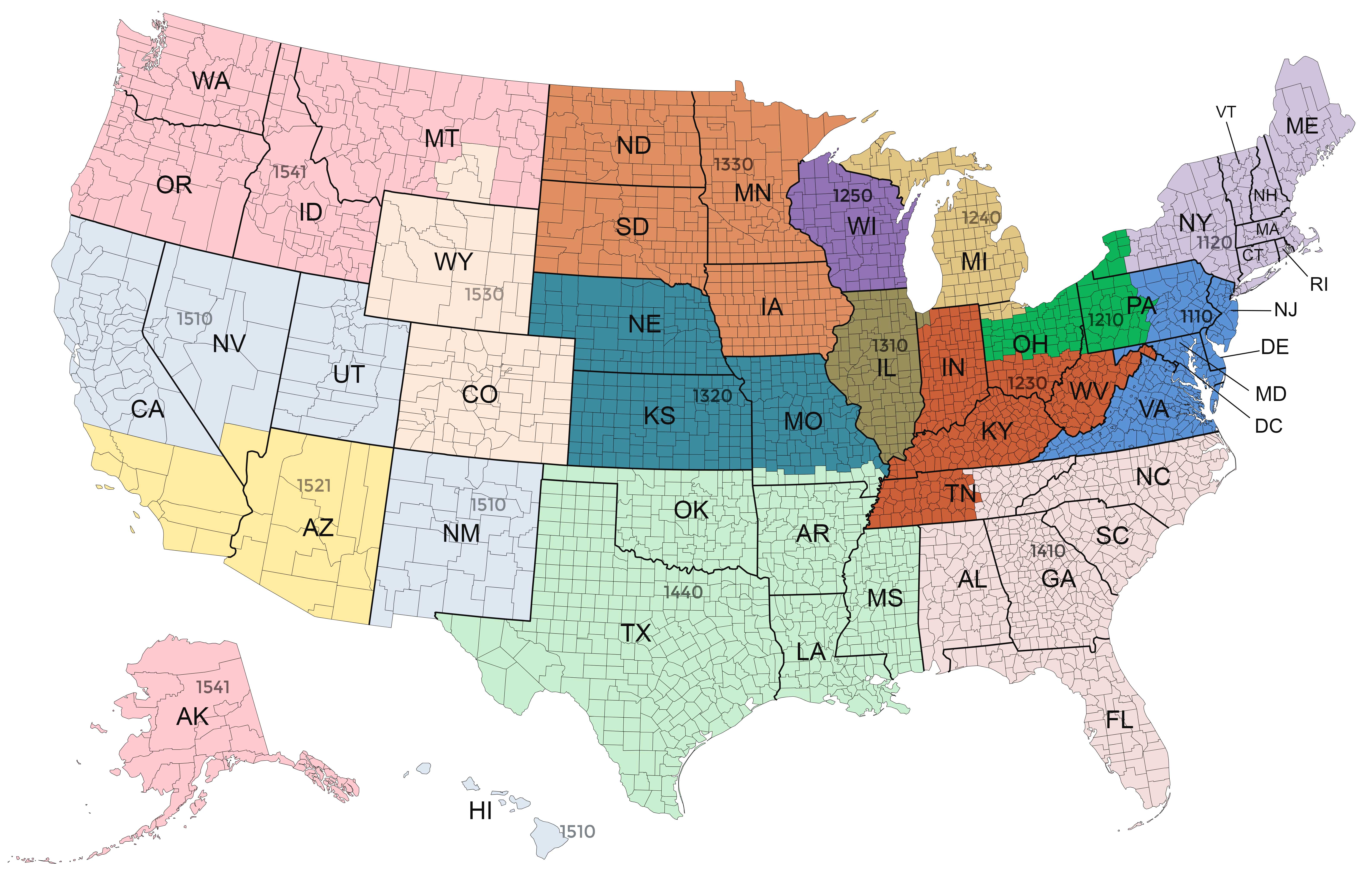

Expert Support in Your Time Zone.

Northwest Motion

Jake Freeberg

jfreeberg@nwmotion.com

+1.425.736.2127

Connor Back

cback@nwmotion.com

+1.503.991.2316

Northwest Motion

Jake Freeberg

jfreeberg@nwmotion.com

+1.425.736.2127

Connor Back

cback@nwmotion.com

+1.503.991.2316

Contour Motion

Raleigh Nielsen

raleigh@contourmotion.com

+1.408.201.2345

Contour Motion

Raleigh Nielsen

raleigh@contourmotion.com

+1.408.201.2345

Western Automation

Pierce Verleur

piercev@waisales.com

+1.949.859.6988

Eric Hodges

erich@waisales.com

+1.949.859.6988

Contour Motion

Raleigh Nielsen

raleigh@contourmotion.com

+1.408.201.2345

Mark Walker

NAMPRO

sales@namproinc.com

Doug Nagle

dougn@namproinc.com

+1.952.240.9720

Evan Reed

evanr@namproinc.com

+1.612.222.5115

Justin Viger

justinv@namproinc.com

+1.763.242.3673

NAMPRO

sales@namproinc.com

Doug Nagle

dougn@namproinc.com

+1.952.240.9720

Evan Reed

evanr@namproinc.com

+1.612.222.5115

Justin Viger

justinv@namproinc.com

+1.763.242.3673

Control Technology Inc.

Terry Carson

tcarson@powermotionsales.com

+1.913.317.8812

Jamie Prewitt

jprewitt@conedrive.com

+1.214.883.4457

Mike Schramer

mschramer@conedrive.com

+1.630.524.3788

Neil Henige

nhenige@conedrive.com

+1.231.944.3001

Martin Bertke

mbertke@conedrive.com

+1.513.604.0444

Mike Williams

mwilliams@conedrive.com

+1.770.993.6463

Peter Johnson

pjohnson@conedrive.com

+1.518.681.1602

Jim Wilkinson

jwilkinson@conedrive.com

+1.231.342.5860

Liggett Co.

Kevin McBrearty

kevin@liggettcompany.com

+1.908.788.8393

Cone Drive’s servo-driven gearing products offer standard, low, and zero backlash options to fit a wide range of servo motor sizes, with custom adaptations available through our responsive engineering team to meet even the most demanding precision applications.

Cone Drive’s NEMA-driven gearing products accommodate a wide range of motor sizes, offering both integrated motor adapter flanges and belt- or chain-driven reducers, all featuring a non-fretting quill design for easy motor removal.

Cone Drive’s cup-style harmonic gearing solutions deliver precise, zero-backlash motion control in compact, high-torque applications, featuring integrated cross-roller bearings, industry-standard mounting interfaces, and full customization to meet specific performance and integration needs.

Cone Drive’s hat-style harmonic gearing solutions are engineered for high-precision, high-torque applications, offering smooth motion, robust load handling, and customizable features such as housed outputs, hollow shafts, sealed designs, and integrated cross-roller bearings for seamless integration in demanding environments.

Cone Drive’s ring-style harmonic gearing solutions are designed for compact, high-precision applications requiring flexible integration, supporting loads through the outer ring and mounting via the circular ID spline—making them ideal for robotics, automation, and space-constrained systems with customizable torque, ratio, and interface options.

Cone Drive’s Service Center provides expert inspection, reverse engineering, rebuild, and repair services for double enveloping worm gears, helical/bevel gearboxes, and planetary systems—using advanced tools like the FARO Edge CMM to deliver precise results and performance-enhancing retrofits, often exceeding original specifications.

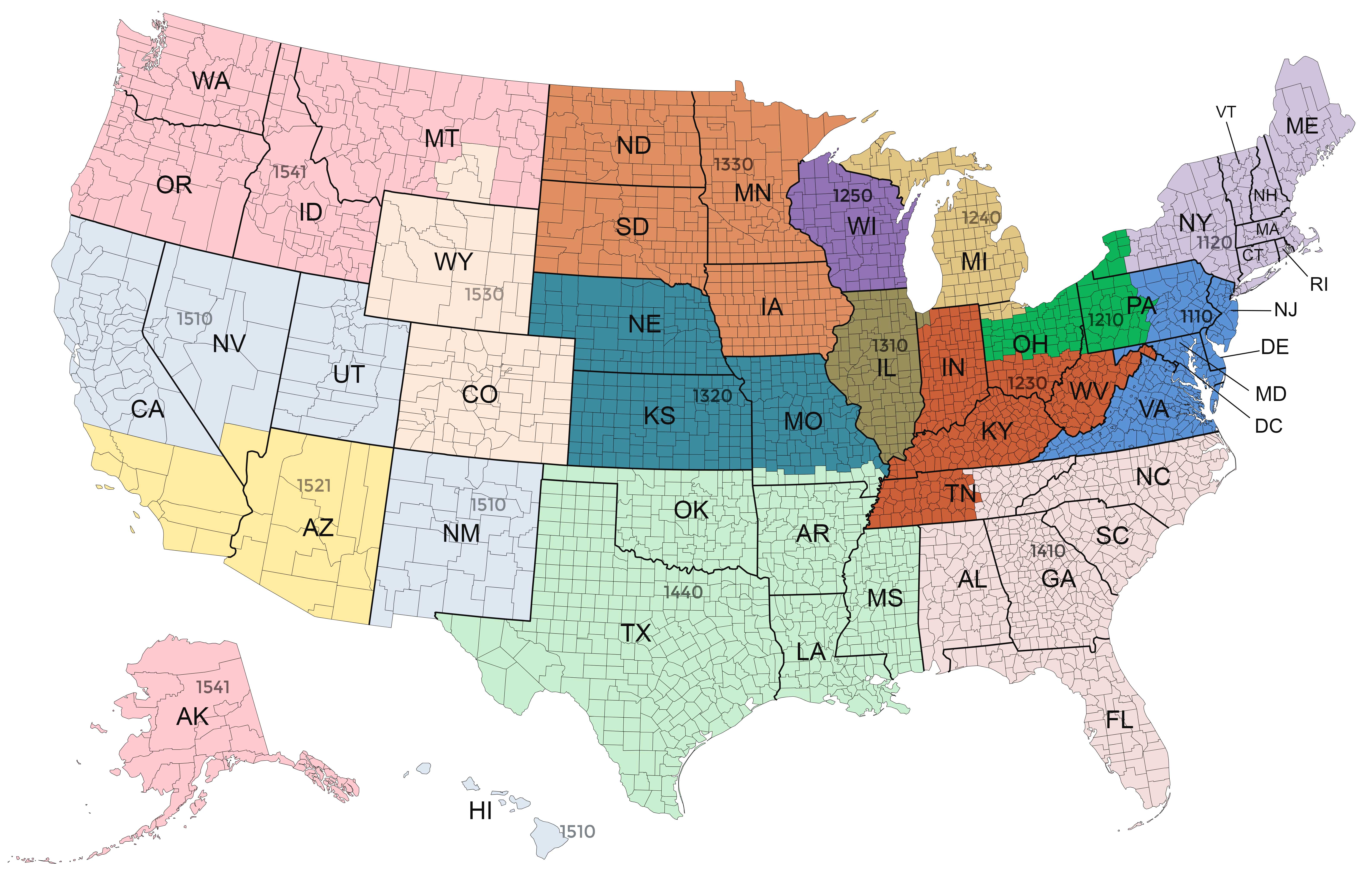

Expert Support in Your Time Zone.

Northwest Motion

Jake Freeberg

jfreeberg@nwmotion.com

+1.425.736.2127

Connor Back

cback@nwmotion.com

+1.503.991.2316

Northwest Motion

Jake Freeberg

jfreeberg@nwmotion.com

+1.425.736.2127

Connor Back

cback@nwmotion.com

+1.503.991.2316

Contour Motion

Raleigh Nielsen

raleigh@contourmotion.com

+1.408.201.2345

Contour Motion

Raleigh Nielsen

raleigh@contourmotion.com

+1.408.201.2345

Western Automation

Pierce Verleur

piercev@waisales.com

+1.949.859.6988

Eric Hodges

erich@waisales.com

+1.949.859.6988

Contour Motion

Raleigh Nielsen

raleigh@contourmotion.com

+1.408.201.2345

Mark Walker

NAMPRO

sales@namproinc.com

Doug Nagle

dougn@namproinc.com

+1.952.240.9720

Evan Reed

evanr@namproinc.com

+1.612.222.5115

Justin Viger

justinv@namproinc.com

+1.763.242.3673

NAMPRO

sales@namproinc.com

Doug Nagle

dougn@namproinc.com

+1.952.240.9720

Evan Reed

evanr@namproinc.com

+1.612.222.5115

Justin Viger

justinv@namproinc.com

+1.763.242.3673

Control Technology Inc.

Terry Carson

tcarson@powermotionsales.com

+1.913.317.8812

Jamie Prewitt

jprewitt@conedrive.com

+1.214.883.4457

Mike Schramer

mschramer@conedrive.com

+1.630.524.3788

Neil Henige

nhenige@conedrive.com

+1.231.944.3001

Martin Bertke

mbertke@conedrive.com

+1.513.604.0444

Mike Williams

mwilliams@conedrive.com

+1.770.993.6463

Peter Johnson

pjohnson@conedrive.com

+1.518.681.1602

Jim Wilkinson

jwilkinson@conedrive.com

+1.231.342.5860

Liggett Co.

Kevin McBrearty

kevin@liggettcompany.com

+1.908.788.8393

Globally Manufactured by Our Team. Locally Supported by Cone Drive.

In addition to our U.S.-made products, Cone Drive offers precision solutions manufactured at our global manufacturing facilities. These products are produced to the same high standards and engineering excellence that define the Cone Drive name. And while their origin may be international, every product is backed by our local support team—offering responsive service, technical expertise, and a direct line of communication. With Cone Drive, you get the advantages of global production with the confidence of local partnership.

CYCLOIDAL GEARING

Cycloidal style gearing providing a lightweight, torque dense solution for applications that require high moment capacity and stiffness.

VIEW →

SLEWING DRIVES AND BEARINGS

Highly-adaptable slew drives and bearings featuring strong shock resistance, long life performance, and smooth rotation.

VIEW →

PLANETARY GEARING

Planetary style gearing providing low backlash and high efficiency in a variety of sizes, styles, and ratios.

VIEW →

SOLAR AND TRACKING GEARBOXES

We have a long standing history of engineering custom solutions. Our products are designed to handle the tight specifications required for the solar and satellite tracking market.

VIEW →

A WORLDWIDE SYSTEM OF SUPPORT

United States

Canada

Desmond O'Keefe

dokeefe@conedrive.com

+1.437.328.2063

Mexico and Central America

Jamie Prewitt

jprewitt@conedrive.com

+1.214.883.4457

South America

Jamie Prewitt

jprewitt@conedrive.com

+1.214.883.4457

Europe

Spinea

info@spinea.com

+421.51.77.00.156

Africa

Mark Walker

mwalker@conedrive.com

+1.330.604.0363

Asia

sales@conedrive.com.cn

+86.510.86366206

Australia

Mark Walker

mwalker@conedrive.com

+1.330.604.0363

PRECISION • MOTION CONTROL • TECHNOLOGY

We design and manufacture worm gears, worm gearboxes, slew bearings, slew drives, harmonic, and cycloidal gearing. With a history of gearbox manufacturing that spans nearly 100 years, we are a world leader in precision motion control technology. With Cone Drive you can always find the right solution for your application with the highest quality products and the lead times you require.

PRODUCT DEVELOPMENT

The Cone Drive Product Development Laboratory is a state-of-the-art facility directly adjacent to our Traverse City, Michigan manufacturing location. The lab has the capacity to test a wide range of gear reducer products, for both Cone Drive products as well as those manufactured by other companies. The lab includes capability to run a wide variety of tests including load testing for evaluating reducer performance and operating efficiency.

TEST + CONTROL

PRODUCT MEASUREMENT

- Six product testing stands

- Servo cyclic control

- Simulated inertial loading

- Constant torque/load

- Durability/validation

- Accelerated life test

- Lubricant evaluation

- Static loading & stiffness

- Displacement & motion

- Torque

- Thermal

- Efficiency

- Vibration

- Basic noise

- Transmission accuracy